Some of you may have heard the term “graphene” being used when describing the ingredients found within various automotive coating products. Heralded as a “miracle material” by the scientific community, graphene oxide is an ultra lightweight, virtually transparent substance that is supposedly 200 times stronger than steel, and serves an outstanding heat and electricity conductor. Very cool, space-age stuff for sure. But does graphene make car coating products more resilient?

Despite being recognized as a breakthrough material by the scientific community, many car care enthusiasts and professionals view graphene oxide enhanced paint protection products as “scammy pseudoscience.” This sort of negative reception is an all too familiar scenario for those in the ceramic coating and paint protection film (PPF) business. Both of these products were also greeted with intense levels of scrutiny when they first hit the scene years ago, as an unsubstantiated fear of the unknown continues to fuel public distrust.

Over here at AvalonKing, we believe that breakthroughs in the realm of car coating protection are always a good thing, regardless of how unorthodox they may appear on paper. Whether it’s a ceramic wax spray that actually works, or a graphene oxide enhanced coating that kicks ass, we’re all for seeing the car care DIY market evolve. But in order for these products to work, they must also be explained in a straightforward manner in order to avoid confusing potential buyers.

After doing some digging on the origin of graphene oxide, we unearthed some pretty startling information, as well as some impressive statistics. We were also able to discern whether or not graphene adequately fulfills its purpose in car care paint protection products, a topic that will surely remain in contention long after this article has gone to print.

Talk Nerdy to Me: What in the Hell is Graphene Oxide Anyhoo?

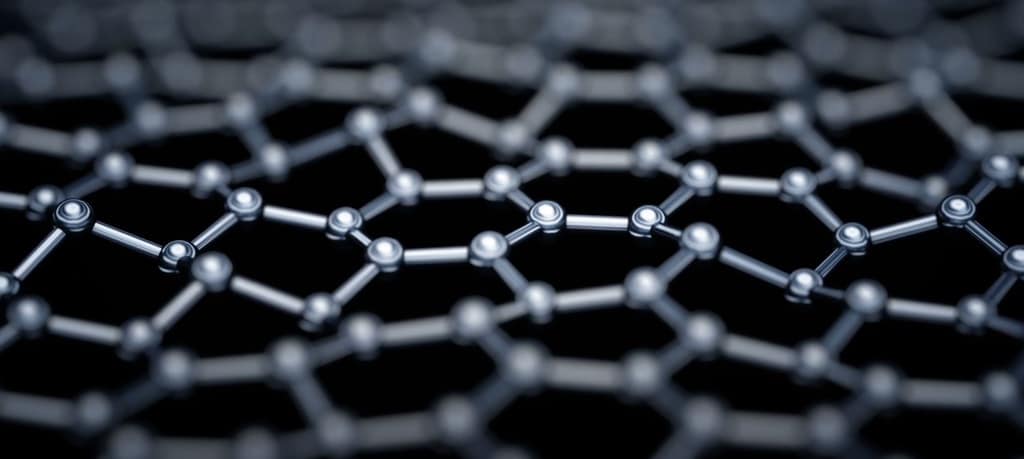

The discovery of graphene oxide came about when a pair of scientists, Andre Geim and Konstantin Novoselov, discovered that by applying regular adhesive tape to chunks of carbon graphite (aka pencil lead), they could obtain a single flake of carbon with the thickness of just one atom. Broken down to its most base, singular atomic carbon form, their discovery resulted in the production of the thinnest and strongest material known to man. In response to this breakthrough research, the two men were later awarded the Nobel Prize in Physics for 2010.

Since graphite is a complex, 3-dimensional crystalline material, breaking it down to a one atom thick grid turns it into a 2-dimesional lattice. Being that there are different thickness levels to graphene oxide, this substance appears clear to the naked eye until about 50 atom layers or more are stacked, at which point it turns opaque.

“Many scientists are optimistic that graphene will one day enhance-or replace-metals and plastics in our daily lives.”

-Smithsonian Magazine

Graphene oxide is also extremely lightweight and conductive, with its temperature thresholds ranging anywhere from 2200-3300°F, which hypothetically speaking, means that it outperforms all other known materials. As an electrical conductor, graphene performs as well as copper, and despite being almost completely transparent, remains so dense that not even helium, the smallest gas atom, can pass through it.

I’m not overexaggerating when I say that graphene is lightweight too. Former president of the International Detailing Association (IDA), Jim Lafeber, says that a 55 gallon drum of this stuff tips the scale at just over 3 pounds after adjusting for the weight of the drum itself!

But Does a Graphene Coating Work?

Despite referring to pure, atomized graphene as a “wonder material,” Lafeber warns that DIY guys and dolls should remain skeptical of any pitch proclaiming that it is the final say in automotive surface protection. After testing the stuff for years, Lafeber found that graphene coatings routinely failed to offer many of the benefits found within a ceramic coating product, and that they typically did not last as long. He went on to explain that while graphene oxide is indeed extremely strong, it also flexes under pressure, making it susceptible to damage when there is a kink in its structure.

After examining and testing multiple graphene coating products, Mr. Lafeber found that many of these offerings only contained trace amounts of the lightweight substance. Being that 5 grams of pure graphene oxide costs upwards of $25-30, Lafeber was not a bit surprised by this discovery. He admits that upon examination, many of these products proved to be little more than bottles of ceramic coating with a dusting of graphene powder added to their contents. Further investigation found that the more nefarious companies were adding no more than a single spec of graphene to their product, before loading the liquid with black dye to mimic the genuine substance.

Fraudulent products unveiled, we turn toward another serious topic of discussion: Does a genuine, high-end graphene coating go onto a surface in a uniform manner, or does it all just reside at the bottom of the bottle, completely impervious to shaking and mixing? According to Lafeber, settling happens with this stuff no matter what you do, therefore it is impossible to force graphene to be uniform in nature, at least, not yet…

Quick Nerd Note: Due to its outstanding heat conductivity attributes, graphene oxide has seen success in a few areas of manufacturing, including electronics, and curiously enough, the clothing industry. Graphene’s mosquito-repelling properties have given it a sharp edge in the clothing industry, with its ability to deflect harmful UV rays giving it a strong advantage as well.

How Does Graphene Stack-Up Against Ceramic Coatings?

Hypothetically speaking, yes, the use of graphene in an automotive protective coating is a brilliant idea. But does it cut the cannoli when compared to the paint protection offered by the latest ceramic coating technology?

Take the “Ethos Graphene Matrix Coating” for instance. A 30ml bottle of Ethos Graphene costs about $100 a pop, and is marketed as a paint protection product that can shield a vehicle’s paintwork from the elements for more than five years before requiring reapplication. Like ceramic coating, the Ethos Graphene Matrix Coating cannot be applied until all wax and bonded contaminants are removed from the vehicle’s paintwork. It is also most susceptible to failure when improper prep work is present.

Prep work complete, along with any mandatory paint correction procedures, the Ethos Graphene Matrix Coating can be applied via a microfiber applicator pad and sponge. After hazing for 1-3 minutes, the Ethos Graphene Coating gets buffed with a clean microfiber cloth, and the application process begins anew in a separate area. In essence, this process is almost identical to the application of a ceramic coating car care product.

After that, it only takes five days for the graphene coating to cure, as opposed to the two weeks mandated for most ceramic pro coatings. However, both graphene and ceramic coating exhibit similarities when you compare their more immediate curing properties. Both require around 24 hours of cure time before they are deemed safe for water contact, and should not be chemical cleaned until curing is 100% complete.

Graphene coating manufacturers claim that when compared to traditional ceramic coating products, water spotting is not nearly as much of an issue. When automotive detailing specialist, Chicago Auto Pros, conducted a full-on “graphene coatings vs ceramic coatings” comparison on a car hood, some interesting results materialized. Once fully cured, the graphene coating sheeted water extremely well, and was resistant to damage from UV rays and high pH chemicals.

However, the graphene coating fell short in other areas, as it did not add as much of a glossy sheen as the ceramic coating, and in the hard water test phase, left heavy water spotting on the surface.

Another issue in the whole, “graphene coatings vs ceramic coatings” slug fest, is this product’s residue. Being that graphene is carbon based, the black leftovers it leaves behind make a royal mess of clothing, making the application process all the more challenging. Graphene oxide may be completely transparent in small amounts, but slap enough of it on a surface, and that greyish graphite dust really comes through.

So while graphene oxide may exhibit some super cool properties, and pack loads of potential for things like space exploration, it seems like we still have a long way to go before this “wonder material” becomes the next evolutionary step in car coatings. That said, we can’t even begin to imagine the possibilities when this space-age material becomes a manufacturing staple. Maybe then we can coat that intergalactic quad-jumper we’ve been fawning over…

13 comments

Liesle

Truth be told. People are still fast asleep where this toxic element is concerned.

Truth be told. People are still fast asleep where this toxic element is concerned.

Leona

FYI graphene oxide is highly toxic because it overrides a bodies production of glutathione, at which point you have cytokine storms and die.

FYI graphene oxide is highly toxic because it overrides a bodies production of glutathione, at which point you have cytokine storms and die.

Armando Reyes Vega.

Muy buena información.

Muy buena información.