How long do you think the average factory paint job can hold up against the elements, before requiring a complete paint correction procedure? Five years? Ten? All the way up until the fateful day that Godzilla accidentally squishes the damn thing?

According to certain automakers, as long as you keep your clear coat clean and protected (and out of Godzilla’s path), there’s a good chance that the modern paint job will last the lifetime of the vehicle.

Unfortunately, humans are not always very good about following directions, and as the frantic pace of daily life takes its toll, so too does our neglect for our automobiles.

As car washes grow increasingly infrequent, and paint protection product installs take a backseat in lieu of more pressing matters, the risk of exposure to harmful contaminants, UV rays, and other damaging factors becomes more of a threat.

One of the more common consequence of clear coat neglect is something called oxidation, which over time can lead to peeling, fading, and an intense sense of shame. While we can’t help you with the guilt side of the situation, we can offer some stellar clear coat repair advice, so dry those eyes and listen up.

But before we delve too deep into the advanced art of clear coat repair, we will need to break down a few facts. In the information below, we’ll explain how modern automobiles are painted, and what causes all those pretty pigments on our vehicles to fade and oxidize.

There will also be an entire section set aside for repair advice and warnings, so expect to find a little bit of everything in today’s blog upload.

The Modern Paint Job Explained

Today’s factory paint jobs are far superior to what our grandparents had to scrub every week. The techniques and chemicals used are cutting edge, making paint spraying far more cost-effective and environmentally friendly, due in part to modern day paint booth robotics, and the advent of more effective hardeners and pigmentation.

While extreme paint schemes do exist (15-layer Acura MDX soccer mom machine anyone?), the modern day paint job tends to revolve around the following four-step process.

The 4-Step Automotive Paint Process

Chemical Treatment: The first step is to chemically strip all grease, oil, and surface contaminants from the bare metal. This typically requires dipping various vehicle components in a chemical bath, or spraying them as they travel down the assembly line. Plastic parts receive a similar treatment, all but with far less abrasive chemicals.

Etching and Sanding: Once the bare metal or plastic is free of debris, the next step is to lightly scratch or etch its surfaces so that the paint will stick. A spray-on chemical will also be implemented at this stage, especially if the part in question is particularly fragile.

Primer: As the soon-to-be-painted part rolls down the surface prep assembly line, it is inspected, and then readied for primer. This matte-colored coating serves as a base for all subsequently sprayed paints to adhere to, and serves as a “last resort” layer of protection for the bare plastic or metal below.

Color and Clear: The final step in the automotive paint process, is the application of pigmented paint, which once fully cured, gets adorned with a transparent clear coat. Most manufacturers opt to spray a few coats of both colored and clear at this stage of the paint process, as it helps ensure even coverage, and adds additional protection from scratches and whatnot.

What Causes Clear Coat Damage?

When you encounter a jalopy cruising down the street, and it’s covered with peeling paint that looks all super shitty and sunburnt, it’s probably not the actual paint that’s looking rough, but the clear coat on top of it.

As the outermost layer of paint, automotive clear coat tends to be the first thing to shit the bed once routine car detailing and paint protection upkeep take a backseat. This invisible frontline of paint defense not only absorbs Mother Nature’s abusive temper tantrums, but it also goes bumper-to-bumper with man-made contaminants as well, including harmful oxidizing agents.

Understanding Oxidation

As the core cause behind most of the world’s crappy-looking clear coats, oxidation continues to be labeled as the most common form of “automotive skin cancer.” While our article on rust prevention goes over some of the science behind this “cancerous car killer,” the clear coat side of the situation is a far more straightforward affair.

While there are countless contributing factors that can cause clear coat oxidation, four primary offenders stand head and shoulders above all others: UV Radiation, Plant and Animal Waste, Chemical Exposure, and Acid Rain.

While such outside influences may not always be able to force a clear coat to fail on its own, these “Four Horsemen of Oxidation” do have the ability to significantly accelerate its degradation, and here’s how they do it…

UV Rays

One of the biggest misconceptions people have about paint oxidation, is that direct sunlight is its root cause. While the sun will definitely do a number on your clear coat if given enough time, it’s not the heat you have to worry so much about, as it is the invisible UV rays contained within a sunbeam.

When allowed ample time to work, UV light becomes a master of clear coat penetration, slowly turning the transparent into the abhorrent. While the defilement of this invisible top layer of paint protection is definitely a concern, it is the UV ray’s ability to heat-up the pigmented paint underneath that is the biggest cause for concern.

As the weakened clear coating begins to bow to the sun’s unyielding barrage of radiation, oxygen begins to seep into the underlying paintwork. As the sunbeam’s heat is absorbed by the plastic or metal surface, it forces the molecules within the clear coat, and paint to relocate, thus causing fading to occur.

Plant and Animal Droppings

Bug guts, bird crap, tree sap, and many other naturally occurring forms of “organic defilement” pose a genuine threat to automotive clear coats. While the sticky side of these unpleasant, and often completely unavoidable occurrences helps contribute to the demise of paint and clear coatings, the acids within this gunk tend to be the core cause of surface oxidation.

Chemical Exposure

Mother Nature isn’t the only one shitting on your car’s clear coat. Many of the world’s man-made chemicals and automotive oriented by-products pose a genuine threat to our vehicles’ exteriors as well, especially since most of them are completely unavoidable.

From road salt and de-icing sprays, to diesel exhaust soot, harsh cleaning chemicals, and car pranks gone wrong, humans truly are their own worst enemy, as our inventions inflict billions of dollars in clear coat oxidation every year. This is why using a pH neutral car shampoo and properly balanced cleaning agents is so crucial in the protection of a vehicle’s paintwork.

Acid Rain

When the unburned carbon molecules that are caused by the combustion of fossil fuels decide to “bump uglies” with the moisture in the air, toxic clouds are formed. Heavily laden with putrid precipitation, the “Acid Rain” threat proves once again that it is a bona fide clear coat killer.

Contrary to its namesake, acid rain is not so much a skin-melting nuisance, but a pollution-rich, pH cluster-fuck of an oxidizing solution. It’s also virtually impossible to avoid, and extremely difficult to detect, because… well… acid rain detecting windshields still have yet to be invented.

Can You Repair an Oxidized Clear Coat?

As you might guess, there are multiple levels to the damage inflicted by paint and clear coat oxidation. As with any kind of surface contamination or chemical exposure, the sooner you can assess the damage and eliminate it, the better.

Determining whether or not you can fix the damage on your own over the course of a weekend, or have to hand the job off to a reputable auto body shop can spell the difference between a quick $50 fix, and a $5,000 repair bill.

Here are a few of the more common forms of clear coat and paint oxidation, listed in order from DIY doable all the way to… “Well there goes our life savings…” levels of severity.

Fading

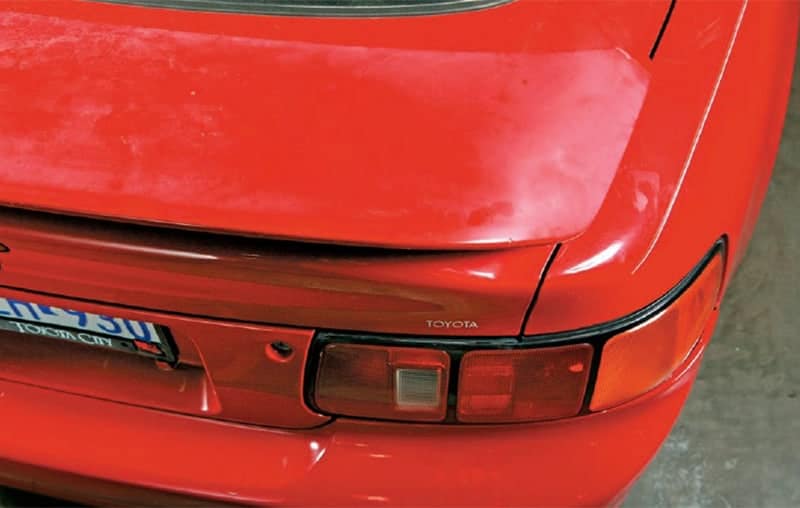

On the right side of this image you can see that this car’s clear coat is beginning to fail. The outermost layer of clear coating has begun to dry out, causing the paint beneath it to appear hazy.

Despite looking like complete crap, this is the automotive equivalent of having a mild sunburn. But instead of throwing some aloe vera at the issue, you need to be hitting that clear coat with some pH balanced car maintenance shampoo for decontamination and moisturizing, followed by a bit of surface buffing.

While this technique may not work on all forms of faded clear coat, the car shampoo and buffing “combo attack” does tend to do the trick the majority of the time, especially when followed by a moisture-rich nano ceramic coating like Armor Shield IX.

Spotting

When the clear coat has surpassed the drying and fading stage, small pockets of exposed paint will begin to appear in damaged areas. This is called “spotting,” and it occurs when the upper layers of the coating become so compromised, that they must be removed via the use of paint correction tools and carefully implemented techniques. For more on this time-consuming process, check out our car detailing article that focuses on paint correction tips for beginners.

Peeling

If the clear coat has gotten to the point where peeling is beginning to be a widespread issue, then there is no other form of recourse, and you must remove the compromised clear coat, and reapply a fresh outer layer of protection.

As for the act of determining whether or not you should attempt the DIY repair of the oxidized clear coating yourself, or contract the job out to a professional body shop, well that is entirely up to you. Spraying layers of fresh clear coat, and getting the finish to look like it just rolled off the assembly line is far easier said than done, as it requires the appropriate tools and experience, as well as a safe place to spray.

Parting Shots

Outside of oxidation, automobile owners also have to contend with things like spider webbing surface scratches, hard water spots, road salt and deicer damage, and paint stains. It’s a never-ending battle between humankind and the crap that is constantly coming into contact with our automobiles.

On the upside, your friends at AvalonKing are always happy to offer some professional advice, and point you toward the best surface cleaners and protectants on the market today. So keep that clear coat clean, and protect it with the highest rated DIY nano ceramic coating on the planet, because nobody needs oxidation in their life, especially when it is trying to ruin your ride.

8 comments

W Waff

Don’t know if I can use a brand (Seal Skin Cover) which leaked in a dozen places…only had it on the car one month….

No blotches on paint when I put it on, but when I took it off there were small, medium, and large paint blotches that are evidently permanent….made in China, I’m thinking that chemicals from this type of cover seeped through with the rain….I would send a before and after picture but don’t see a way to send….

Don’t know if I can use a brand (Seal Skin Cover) which leaked in a dozen places…only had it on the car one month….

No blotches on paint when I put it on, but when I took it off there were small, medium, and large paint blotches that are evidently permanent….made in China, I’m thinking that chemicals from this type of cover seeped through with the rain….I would send a before and after picture but don’t see a way to send….

Dave

You’ll damage the base coat and it will look like crap. I’ve been painting cars for 35 years. The only wat to fix it right is to start l over again. Strip off the clear most the damaged base coat, epoxy prime the surface, sand base and clear. Only way it will look great and last along yime

You’ll damage the base coat and it will look like crap. I’ve been painting cars for 35 years. The only wat to fix it right is to start l over again. Strip off the clear most the damaged base coat, epoxy prime the surface, sand base and clear. Only way it will look great and last along yime

TIM S

Was there ever a follow up to “discuss a few ways of determining whether you should attempt a DIY repair of oxidized clear coats”?

Was there ever a follow up to “discuss a few ways of determining whether you should attempt a DIY repair of oxidized clear coats”?

Larry Martin Arms

Very helpful, thank for the info.

Very helpful, thank for the info.

Alejandro Molina

why not remove all the clear coat and put a better new one on?

why not remove all the clear coat and put a better new one on?

Tim C

Thanks John.

Thanks John.

Don Baxley

You do not need to put any protectant over a quality clear coat that was put over a quality base coat. Just keep it clean. That is what a clear coat is. It is the protectant. Peeling comes from heat then UV rays breaking the bond between the the clear coat and the base paint. Also from just poor clear coat or contamination when applying. Car manufacturers in the last 15 years use cheaper base paint and cheaper clear coats to save money. So today, if you are smart, you do need to protect the protectant from failing. Lol, the very purpose of why clear coat was first invented! Back in the 1970’s when clear coating came out it was common for clear coats to last 15 + years if you kept the car clean. In fact they advertised clear coats as never needing to be waxed again. Today many cars have their clear coat peel in only 5 less years. Pisses me off!

You do not need to put any protectant over a quality clear coat that was put over a quality base coat. Just keep it clean. That is what a clear coat is. It is the protectant. Peeling comes from heat then UV rays breaking the bond between the the clear coat and the base paint. Also from just poor clear coat or contamination when applying. Car manufacturers in the last 15 years use cheaper base paint and cheaper clear coats to save money. So today, if you are smart, you do need to protect the protectant from failing. Lol, the very purpose of why clear coat was first invented! Back in the 1970’s when clear coating came out it was common for clear coats to last 15 + years if you kept the car clean. In fact they advertised clear coats as never needing to be waxed again. Today many cars have their clear coat peel in only 5 less years. Pisses me off!

John B Silverio

Your blog proved to be very informative and direct to the point. We have old neglected cars and a new baby, I mean, car arriving in the next few months so I’ll have to deal with extremes in terms of care. Thanks.

Your blog proved to be very informative and direct to the point. We have old neglected cars and a new baby, I mean, car arriving in the next few months so I’ll have to deal with extremes in terms of care. Thanks.