What is Hardness Scale? Explained by AvalonKing

The hardness scale is a critical concept in the world of ceramic coatings. It is a measure of the resistance of a material to surface indentation or abrasion. This scale plays a pivotal role in determining the durability and effectiveness of ceramic coatings. AvalonKing, a leading name in the ceramic coating industry, relies heavily on this scale to develop high-quality products that offer superior protection.

Understanding the hardness scale can be complex, but it's essential for anyone interested in ceramic coatings. Whether you're a car enthusiast looking to protect your vehicle or a professional in the coating industry, this knowledge can be invaluable. In this glossary entry, we will delve deep into the hardness scale, breaking down its various aspects and explaining its relevance to ceramic coatings.

The Concept of Hardness

Hardness, in the context of materials science, refers to the ability of a material to resist deformation, usually by indentation. The harder a material, the more resistant it is to various forms of wear and tear, including scratching, denting, and bending. This property is particularly important in the context of protective coatings, where the hardness of the coating can directly impact its protective capabilities.

Hardness is typically measured using one of several scales, including the Mohs scale, the Rockwell scale, and the Vickers scale. Each of these scales uses a different method to measure hardness, but all essentially involve applying a known force to a material and measuring the resulting indentation.

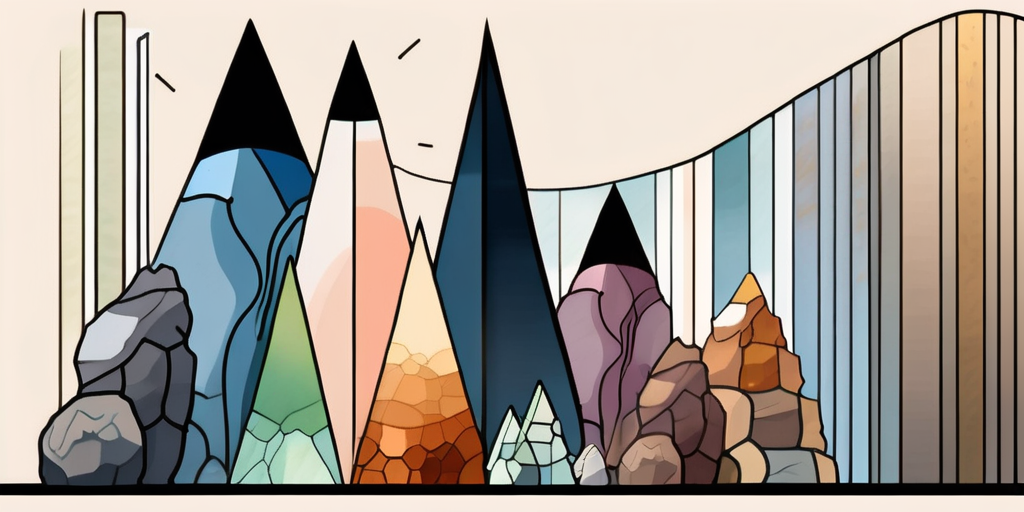

Mohs Scale

The Mohs scale, named after Friedrich Mohs, a German mineralogist, is one of the most commonly used hardness scales. It ranks minerals on a scale from 1 (softest) to 10 (hardest). The scale is based on the ability of one mineral to scratch another. For example, if mineral A can scratch mineral B, then mineral A is harder than mineral B.

While the Mohs scale is widely used in geology, it is less commonly used in the ceramic coating industry. This is because the scale is not linear, and the difference in hardness between each successive level varies. For example, diamond (10 on the Mohs scale) is four times harder than corundum (9 on the Mohs scale).

Rockwell Scale

The Rockwell scale, named after Hugh M. Rockwell and Stanley P. Rockwell, is another commonly used hardness scale. Unlike the Mohs scale, the Rockwell scale is used extensively in the ceramic coating industry. This scale measures hardness by determining the depth of penetration of an indenter under a large load compared to the penetration made by a preload.

There are several different versions of the Rockwell scale, each using a different indenter and different loads. The most commonly used versions in the ceramic coating industry are the Rockwell C and B scales. The Rockwell C scale is used for harder materials, while the B scale is used for softer materials.

Hardness in Ceramic Coatings

Hardness is a crucial property in ceramic coatings. The harder the coating, the more resistant it is to scratches, dents, and other forms of damage. This is why ceramic coatings are often marketed based on their hardness. For example, a 9H ceramic coating is often advertised as being resistant to scratches and able to protect the underlying surface from damage.

However, it's important to note that hardness is not the only property that matters in a ceramic coating. Other properties, such as adhesion, flexibility, and chemical resistance, are also important. A coating that is very hard but lacks flexibility, for example, may be prone to cracking or chipping. Therefore, it's important to consider all of these properties when choosing a ceramic coating.

Measuring Hardness in Ceramic Coatings

The hardness of ceramic coatings is typically measured using the pencil hardness test. This test involves using pencils of varying hardness to make a mark on the coating. The hardest pencil that does not leave a mark is considered the hardness of the coating. For example, if a 9H pencil does not leave a mark, but a 10H pencil does, the coating is considered to have a hardness of 9H.

It's important to note that the pencil hardness test is not a perfect measure of hardness. It is a subjective test, and the results can vary depending on the person performing the test and the conditions under which the test is performed. However, it is a quick and easy way to get a general idea of the hardness of a coating.

Hardness and Durability

While hardness is an important property in ceramic coatings, it's not the only factor that determines the durability of a coating. Other factors, such as the coating's adhesion to the underlying surface, its resistance to chemicals, and its ability to withstand UV radiation, also play a role. Therefore, while a harder coating may be more scratch-resistant, it may not necessarily be more durable overall.

For example, a coating that is very hard but has poor adhesion may be prone to peeling or flaking, reducing its overall durability. Similarly, a coating that is resistant to scratches but not to UV radiation may degrade quickly when exposed to sunlight, reducing its lifespan. Therefore, when evaluating the durability of a ceramic coating, it's important to consider all of these factors, not just hardness.

Hardness Scale in AvalonKing Products

AvalonKing, as a leading provider of ceramic coatings, places a strong emphasis on the hardness of its products. The company's flagship product, Armor Shield IX, boasts a hardness of 9H on the pencil scale. This makes it one of the hardest ceramic coatings on the market, capable of providing superior protection against scratches and other forms of damage.

However, AvalonKing also recognizes that hardness is not the only factor that determines the performance of a ceramic coating. The company's products are also designed to provide excellent adhesion, chemical resistance, and UV resistance, ensuring that they offer comprehensive protection. This balanced approach to product design is one of the reasons why AvalonKing's products are so highly regarded in the industry.

Armor Shield IX

Armor Shield IX is AvalonKing's flagship ceramic coating product. It boasts a hardness of 9H on the pencil scale, making it one of the hardest ceramic coatings on the market. This hardness allows Armor Shield IX to provide superior protection against scratches, helping to keep your vehicle looking its best.

But Armor Shield IX is not just about hardness. The product also offers excellent adhesion, ensuring that it stays firmly attached to the surface it is applied to. It is also highly resistant to chemicals and UV radiation, making it a durable and long-lasting solution for protecting your vehicle.

Application of Armor Shield IX

Applying Armor Shield IX is a straightforward process that can be done by anyone, regardless of their experience with ceramic coatings. The product comes with detailed instructions that guide you through the process step by step, ensuring that you get the best possible results.

Once applied, Armor Shield IX forms a hard, protective layer on the surface of your vehicle. This layer is resistant to scratches, chemicals, and UV radiation, helping to keep your vehicle looking its best for longer. And because Armor Shield IX is so hard, it can even help to protect against minor dings and dents, adding an extra layer of protection for your vehicle.

Conclusion

The hardness scale is a critical tool in the ceramic coating industry, helping to measure the resistance of a coating to scratches and other forms of damage. AvalonKing, with its emphasis on creating hard, durable coatings, makes extensive use of this scale in its product development process.

However, as we've seen, hardness is not the only factor that determines the performance of a ceramic coating. Other factors, such as adhesion, chemical resistance, and UV resistance, are also important. By understanding all of these factors and how they interact, you can make a more informed decision when choosing a ceramic coating for your vehicle.

Ready to give your vehicle the ultimate protection and shine? Check out our products at AvalonKing, where we combine years of expertise with cutting-edge technology to bring you top-tier ceramic coatings, car shampoos, and a wide range of vehicle cleaning solutions. Experience the difference with AvalonKing and keep your car looking immaculate.