Who here remembers the Michael Jackson flick “Moonwalker?” Surely some of you can recall this bizarre cinematic venture from 1988. Hell, Moonwalker wasn’t even a film. It was more of a musical montage, embellished with crappy claymation, dizzying dance-offs, drug king pins, and staged scenes of the pop superstar escaping henchmen in a wild, wedge-shaped supercar. For us petrolheads, being forced to watch that mess of a musical mash-up was about as enjoyable as a root canal, but the moment that space-age supercar hit the screen our jaws dropped.

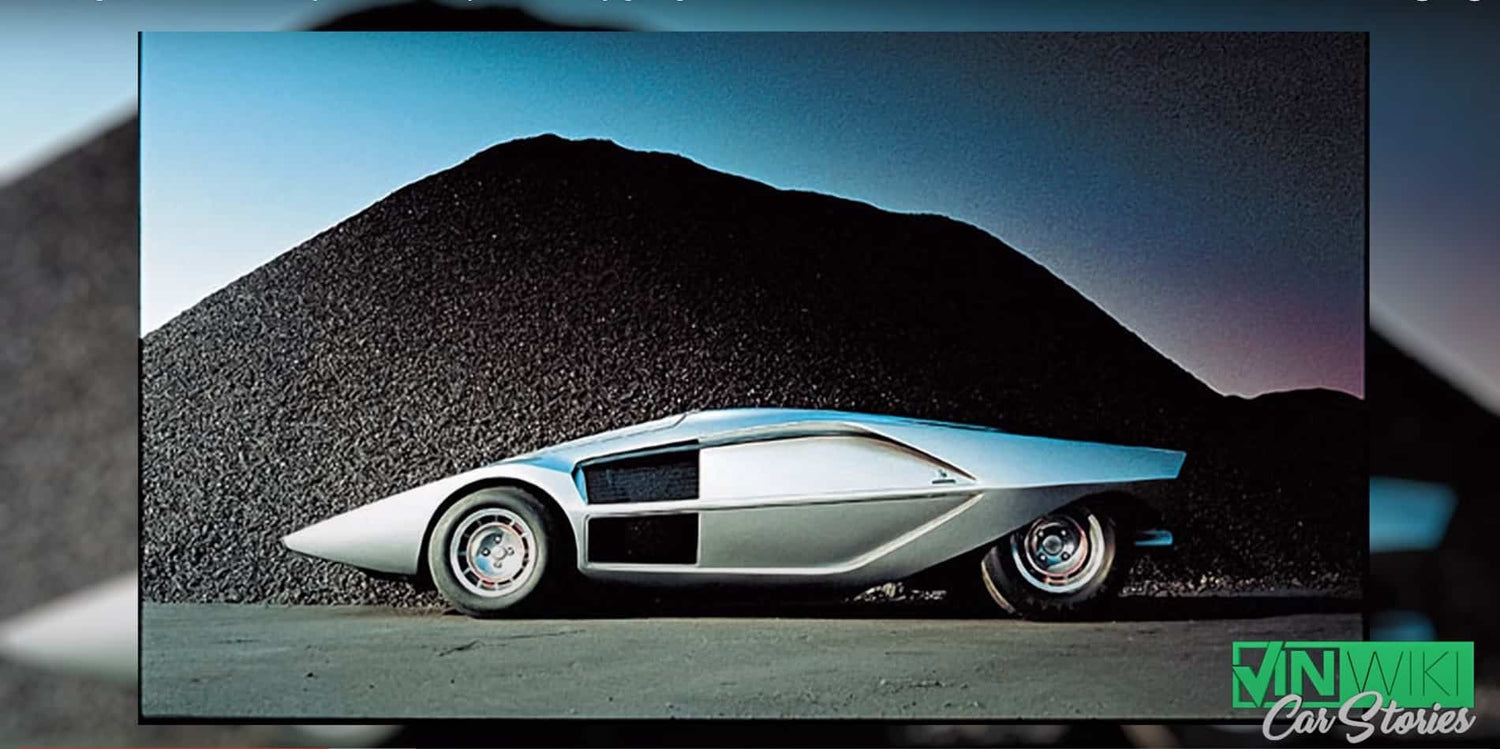

The vehicle I am referring to is the Lancia Stratos HF Zero. A machine that never made it past the prototype/concept car phase, thus rendering it an eternally unattainable slice of automotive forbidden fruit… until now.

When famed vintage race car driver, master fabricator, and YouTube star Casey Putsch told us that he was blowing all of AvalonKing’s sponsorship dollars on recreating this iconic supercar, more than just an eyebrow was raised. While the oddball build proposal certainly caught us off guard, we soon realized that Putsch was on to something, and the more we heard the better this build sounded.

Credit: Casey Putsch

Putsch explained that he wanted to recreate the 1970 Lancia Stratos HF Zero as a fully functional street machine, complete with surefooted suspension and a powerplant befitting of a supercar. He also proposed that in order to keep costs down, the majority of the vehicle would be almost entirely constructed out of sheet metal, spare parts, and aftermarket bolt-ons.

And then came the kicker. Mr. Putsch touted that he could construct the entire vehicle in his garage in just a few months, and did not require any outside assistance save for that offered by his apprentice, Peyton. Putsch went on to explain that if planned properly, the entire project would likely cost less than $20,000.

Needless to say, the powers-that-be over at AvalonKing were quite intrigued by this proposal, and after some deliberation, concluded that the world does indeed need more hand-made 1970s supercar prototypes. And so we agreed to team-up with Casey Putsch, and sponsor what would soon become known as the “Project King Zero” supercar.

“We wanted to do something completely different from the traditional Lambos, or crash rebuilds… we wanted to do something completely unique.”

-Dave Hall, co-founder of AvalonKing

The title “King Zero” is a hybridized title, one that takes the latter part of the AvalonKing brand name, and fuses it with the tail end of the Lancia Stratos HF Zero. An instantly recognizable nameplate, that we feel pays homage to both sponsor and vehicle alike.

Like many automotive purists, Putsch feels that despite all of their smart, swanky, and super swift strong-suits, the modern supercar has no soul, and requires minimal skill to pilot. His goal was simple: Recreate the iconic supercar with more modern and practical attributes, and make it completely drivable, all while stylistically keeping it as true to the original as possible.

Credit: Casey Putsch/YouTube

Sure, Putsch’s plan sounded bonkers at first, but so did the concept of putting a man on the damn moon. While he may not be an astronaut (yet), Casey Putsch is the sort of guy you want to bankroll, because quite frankly, everything he has crafted to date has been nothing short of badass. From his one-off, turbine-powered Batmobile and the work he has done with the VINWiki crew, to Genius Garage, his mentoring program for aspiring engineering students, there is little that Putsch cannot accomplish.

“I decided to not do the commercials with AvalonKing… It would be way cooler to build a supercar.”

-CASEY PUTSCH

Credit: Casey Putsch/YouTube

As one one build update after another materializes on Casey Putsch’s YouTube channel, a revelation dawned upon me. With the right tools, some modest sponsorship dollars, and a little bit of time, creativity, and experience, almost anyone can craft a V12 supercar in their garage for next to nothing. Still not convinced that it’s possible? Let’s get you up to speed…

What is Project King Zero?

Credit: VINWiki/YouTube

Broken down to its bare bolts, Project King Zero is old school supercar building in its purest form, something which Putsch informs us is “not that hard of a task.” That said, this build certainly has come with its fair share of challenges. There are no instructions here, just old school fabrication know-how, and a passion for recreating one of the craziest concept cars of all time.

During a recent Skype video interview, Putsch told us that the task of plotting a direction that would be financially feasible, while still paying homage to the original Zero was his first hurdle. But as time went on, the master fabricator quickly realized that tight build budgets and a commitment to staying true to the vibe of the first incarnation of the Stratos Zero was only a small slice of the supercar pie.

When Marcello Gandini revealed the original Stratos Zero prototype over fifty years ago, people were stunned not only by its futuristic styling, but by the sheer size of the microscopic machine. Measuring a mere 141 inches in length, and just 33 inches in height, Gandini’s masterpiece was slight of stature on every level. Right away, Putsch knew that these dimensions were going to be extremely difficult to work around, especially if he was going to utilize the chassis he had stowed in the back of his mind. So Putsch tossed the notion of building an exact replica of the original, and after sketching-out some blueprints, began to fabricate a slightly larger, modern day representation of the Stratos Zero.

Credit: Casey Putsch

When asked how his one-off King Zero renderings came to fruition, Putsch laughed and told me that since there has never been an off-the-shelf Stratos Zero kit car option, he had to design the entire vehicle from the ground up. In true Putsch fashion, the Ohio native skipped all of the modern computer design programs, and opted to use his creativity to conceptualize his rendition of the Italian supercar. With the help of a projector, a measuring tape, one big-ass roll of paper, a few markers, and some archaic design tools, Putsch was able to sketch a series of life-size blueprints of the King Zero prototype.

Credit: Casey Putsch

Standing about 8.9% larger than the original model, but with all of the right design cues in play, Putsch’s King Zero supercar is part George Jetson space ship and part “psychotic go-kart skateboard.” The public is loving it too, as every week, thousands of subscribers flock to Putsch’s YouTube channel in order to witness the metamorphosis of one of the world’s most peculiar project cars.

Credit: Casey Putsch

Quick Nerd Note: Casey Putsch’s primary assistant on Project King Zero is Peyton McAllister. A young man who recently graduated from Putsch’s Genius Garage engineering mentoring program, only to return in 2020 for a second serving of mechanical mayhem. But this time around, McAllister is tackling an apprenticeship program, a crucial cornerstone in the bridge between academia and professional coach building. It is this highly competitive position that Putsch’s young apprentice pines for both day and night, as Project King Zero provides all manner of experience to aid the young man in his quest for a coach building career.

Credit: Casey Putsch/YouTube

Tools of the Trade

Credit: VINWiki/YouTube

In order for Putsch to build a V12 supercar in his garage, he needed to have an armada of instruments on hand. From welding equipment and reciprocating saws, to engine hoists and fabrication hammers, the list of required gear is substantial. However, Casey Putsch is a bit more advanced than the average bloke who only tackles routine car maintenance on the weekends. After decades of building, racing, and restoring automobiles and motorcycles, the guy has pretty much every tool imaginable at his disposal, and that in itself, makes Prokect King Zero that much more feasible.

“What I wanted to do with this King Zero build, and this BMW V12, is I want to build something evocative.”

So while getting the right equipment together to build the King Zero supercar merely required taking inventory and ordering a handful of tools and supplies, the act of sourcing the components for said supercar was a bit more challenging. Most people would sooner cut corners and buy a partially completed kit car from a reputable seller than spend the energy sourcing the components needed for fabricating everything from scratch. Putsch is not one of these people. He knows that in order to protect your car from the damage inflicted by inferior products, one must build the entire vehicle from the ground up, and then reinforce the ever loving hell out of it.

Credit: Casey Putsch/YouTube

V12 Engine Options and Challenges

Credit: Casey Putsch

While they may have the upper claw when it comes to curb weight, throttle response, horsepower, torque, and downforce, the supercar of today is but an electronically enhanced shadow of the visceral mechanical sensation one feels when piloting a vintage supercar. Manual gearboxes have given way to dual-clutch automatic transmissions, traction and stability are all easily obtainable with the push of a button, and the throaty roar of a vengeful V12 has been replaced by forced induction fumes.

Quick Nerd Note: While we’re on the topic of V12 engines, it is worth noting that while these massive motors are becoming exceedingly rare, they are not completely unattainable. To keep costs down, seek out older V12-powered cars like the Aston Martin DB7 or DB9, the Jaguar XJS, or even a Mercedes C215 CL-Class or Benz’s W220 S600 chassis. Putsch skipped all of these offerings in favor of the BMW E38 750iL, a powerplant that is arguably one of the most reliable and readily available V12 engines ever made.

Credit: Casey Putsch

While finding one of these motors along with its harness already removed from the vehicle eliminates the task of finding a home for the rolling chassis, there are some perks to purchasing the entire vehicle. If the car itself is in fair condition, chances are that you can recoup some expenses by selling the shell to an enthusiast. Even with faded paint and all of the dings associated with nearly 30 years of driving, the demand for the BMW 750iL chassis remains steady. Putsch for instance, obtained this stately red sedan in running (yet slightly leaky) condition for $1,300, and after pulling the motor and harness, sold the rolling chassis for $1,000.

Being that the only affordable V12 options on the market are those offered by European automakers, reliability remains a concern, hence Putsch opting for the more mechanically sound, and readily available BMW engine. Although the donor engine had some leakage issues, there was nothing catastrophically wrong with the BMW V12, and thus little more was required outside of a routine motor makeover.

“Be reasonable when thinking of engine swaps. Don’t get blinded by horsepower, numbers, and money.”

-CASEY PUTSCH

Credit: Casey Putsch/YouTube

Although the challenge of stuffing a BMW V12 into the ass of a tiny Porsche definitely caused some head scratching, one of the greatest snags pertained to the task of mating the motor to the Porsche’s manual gearbox.

However, with the help of a modified adapter plate that affixes to the transmission’s bellhousing, Putsch was able to find a way to make the crossbred powertrain a feasible option. With the task of finding a suitable spot for the radiator and fuel cell now complete, and front subframe and undertray installed, Putsch and Peyton turned toward the daunting task of aerodynamics and chassis reinforcement.

Let’s Skip the Kit and Fabricate That Shit From Scratch

Credit: Casey Putsch

With his $300 V12 engine and wiring harness obtained, Putsch shifted his focus toward the chassis he planned on building the supercar around. The automotive mad scientist had gone with the Porsche Boxster chassis based upon its availability, affordability, and its MacPherson front suspension, mid-engine layout, which mimics the original prototype. This mass produced slab of stamped steel also came with a manual gearbox and a wheelbase that matched Putsch’s design plans perfectly.

Scuttled Boxster obtained for next to nothing, Putsch and Peyton proceeded to hack-up the Porsche, until all that was left were some shock towers, a bit of bracing, and a floor pan. Unlike most YouTube builds, the boys had foregone the kit car approach in favor of a “hack-and-weld” method.

Credit: Casey Putsch/YouTube

Since the old “plug-and-play” direct approach doesn’t apply here (a far cry from Putsch’s car cleaning and ceramic coating feature), Project King Zero has remained quite affordable thus far. This not only made the sponsorship side of things more feasible, but it also left ample space for exploring some of Putsch’s more off-the-wall design ideas.

“This car is genuinely a labor of love. It has nothing to do with money. It’s all about using your imagination and following your dreams.”

Most recently, the boys had to come up with a solution for what Putsch likes to refer to as, “…the floppy noodle with cheese that is the remnants of the old chassis.” Stripped of support, the old Porsche shock towers sagged, offering little rigidity to the exposed chassis. In order to solidify these crucial suspension housing units, Putsch tells us that they planned to affix these towers to the rest of the chassis with triangulated cross beams, much like what one might find in older F1 cars.

Credit: Casey Putsch/YouTube

Putting the Pedal to the Metal, and the Road That Lies Ahead

Credit: Casey Putsch

Like the Lykan supercar built by Putsch’s Genius Garage mentoring program attendees, Project King Zero will likely be put through its paces on track before being unleashed on the open highway. Being that the vehicle came with a title (there is a Porsche Boxster chassis in there somewhere), there’s also a solid chance that this machine will be completely street legal once complete.

Until then, Putsch and his trusty partner in grime, Peyton, have their hands full getting Project King Zero wrapped-up. Recent upgrades include the addition of a custom coilover suspension setup, shock tower and front end reinforcement, undertray welding, and the mating of the engine to that one-off transmission adapter plate that was mentioned earlier. These core components successfully test-fitted, the duo returns to the topic of chassis reinforcements and the metric mess-load of welding and sheet metal fabrication required to craft the exterior.

Credit: Casey Putsch

Putsch is not ashamed to admit that Project King Zero has been his most ambitious venture to date. There are no shortcuts here, so you won’t be seeing any quick fixes or cutting corners here. Since Putsch despises unreliable engineering, the level of quality care that he has poured into this project has been above and beyond anything we could imagined. Not just as a sponsor, but as automotive enthusiasts with a distinct affinity for seeing things done the old fashioned way.

“With this build

-CASEY PUTSCHI’m bringing back the art of driving and the art of cars. I hope it inspires you guys to do the same.”

Putsch admits that while the build has seemed daunting at times, he is looking forward to the coach-building work that awaits. His decision to utilize inexpensive steel sheet metal instead of carbon fiber or aluminum has given him the opportunity to weld the bodywork to various support arms and the remnants of the Porsche subframe. This will not only make for easier, faster, and cleaner welds, but by creating his own body kit out of steel, Putsch will be able to add an extra level of rigidity to the chassis.

Credit: Casey Putsch

Circling back to our Skype interview, Putsch tells us that since he only has to build one of these machines, he plans on pulling-out all of the stops. So head on over to the Casey Putsch YouTube channel to see what he has in the hopper this week, and stay tuned, as we explore more of the underlying ingenious and unorthodox build components going into making the AvalonKing KingZero V12 supercar a reality. Last we heard there was talk of putting cupholders inside the cockpit for bottles of pH balanced water. Why? Because nothing says “swanky” quite like hopping out of your hand-built supercar with a glistening bottle of reverse-osmosis H20 in hand.

Credit: VINWiki/YouTube

2 comments

Karsten Herold

I can´t find a video with the finish and first test drive of the bone crashing King Zero 12 V !?

I can´t find a video with the finish and first test drive of the bone crashing King Zero 12 V !?

David Tyler

Im doing a v12 in a 73 triumph Stag for the same aesthetic reason - good to hear there are more important things other than a ls engine.

if you are interested in other options other than puting the bmw engine management systems into the King Zero car --there are some options that i think would be good i found putting the BMW engine management system was a problem others i have talked to have said the same thing

Im doing a v12 in a 73 triumph Stag for the same aesthetic reason - good to hear there are more important things other than a ls engine.

if you are interested in other options other than puting the bmw engine management systems into the King Zero car --there are some options that i think would be good i found putting the BMW engine management system was a problem others i have talked to have said the same thing