One of the most consistent inquiries we get on a weekly basis, is how to properly blend and use IPA spray. And no, we aren’t talking about brewing up a dank batch of resin-rich India Pale Ale and spritzing your vehicle with hoppy goodness.

While it technically is alcohol, this type of “IPA” stands for isopropyl alcohol, and it’s application is one of the most crucial, and incredibly simple steps in the ceramic coating surface prep process.

So if it’s so easy to apply and important, what’s with all the confusion? Well, part of that has to do with all of the ceramic coating myths that been spiraling around the internet.

In order to cut through crap, let’s go over precisely what isopropyl alcohol is, what it does, and why you must use it as a final precaution in the ceramic coating prep process.

While we’re at it, we might as well talk about the different IPA strength/concentration levels, and how the right blend of this stuff can play a pivotal role in nano ceramic coating adhesion.

What is IPA Spray?

Isopropyl alcohol is essentially the same thing as rubbing alcohol, it’s just a tad more difficult to pronounce and spell.

This ubiquitous disinfecting product comes in an array of alcohol concentration levels, including 50%, 70%, 91%, and 99%, and continues to be a go-to for anyone looking to disinfect a surface.

But for many DIY detailers, having a wide array of alcohol strengths can be problematic, especially if mathematics are not a forte.

Unsure as to which strength grade to purchase, fledgling DIYers fear that by making too strong of a batch, they will somehow melt their vehicle’s clear coat. In contrast, there’s also the concern that by concocting too weak of a solution, you will waste your time, money, energy, and resources on a spray that’s not worth a hoot.

Well let’s forego all of the unfounded fretting and set the facts straight for once, shall we?

A properly diluted IPA prep spray will contain anywhere from 10-25% alcohol, to 90-75% distilled water. How aggressive you make your homemade spray is really up to you, so measure carefully, and keep it within the parameters listed within this guide.

Quick Nerd Note: A while back, a handful of self-proclaimed “online experts” decreed that the application of an isopropyl alcohol blend on a car’s clear coat will cause it to instantaneously shit the bed. This is a massive bag of crap. Unless it’s allowed to sit for a prolonged period of time, a correctly blended isopropyl alcohol spray WILL NOT harm an automotive clear coat.

IPA Spray’s Role in the DIY Nano Ceramic Coating Prep Process

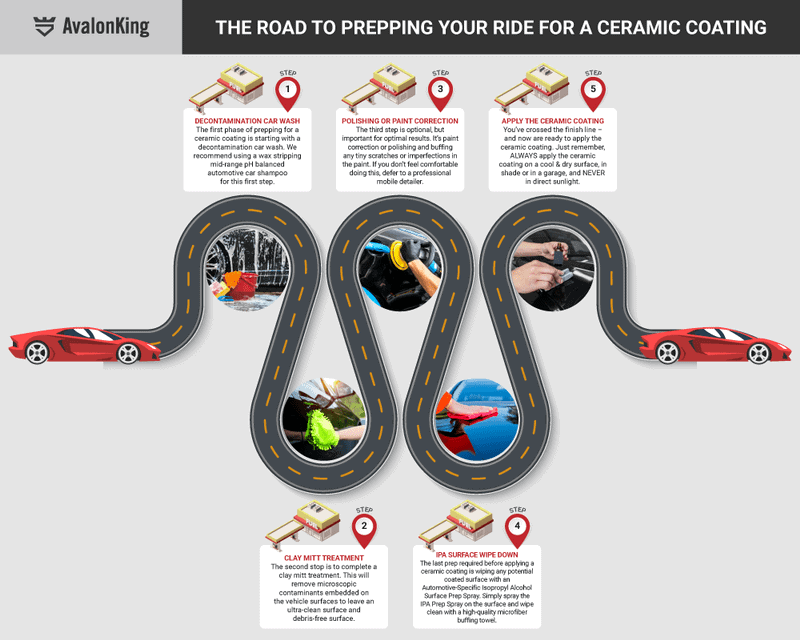

While the ceramic coating prep process may be time consuming, it is far from being something one might call complicated.

Once hand washing and drying is complete, followed by a few rounds of surface claying and paint correction, your vehicle will be itching for a little IPA action, and here’s why.

While all of those initial surface prep procedures will do a solid job of removing previously applied waxes, ceramic coatings, and surface contaminants, the debris that is left in their wake can be substantial. Compounding the matter, is the fact that most of this crud is completely undetectable by the human eye, which is precisely where the IPA “spray and pray” approach comes in.

Since a nano-ceramic coating is engineered to penetrate all of the imperfections and pores in a surface, the removal of any residue from these microscopic pockets and blemishes is vital to your success. You need a product that can kick ass and cut through all of that oil and residue, all while not damaging the clear coat, plastic, or glass underneath.

This is precisely why professional paint shops and experienced DIY detailers alike use a diluted isopropyl alcohol solution on surfaces prior to applying a paint protection product. Not only is IPA spray extremely effective, but once properly diluted and wiped away in a timely fashion, it is completely safe to use on exterior automotive surfaces.

Quick Nerd Note: Polishes and cutting compounds contain carrier oils that allow the gritty media within them to both grasp onto a surface, and be spread evenly during application. Isopropyl alcohol breaks down these oils, as well as the surface contaminants that are “exfoliated” during the paint correction and buffing processes. The result: A clean slate for you to work with that is ripe for nano ceramic coating.

How to Get the Correct Alcohol-to-Water Ratio

When it comes to formulating a balanced IPA spray solution, mindful measurements, distilled water, and knowing the strength of the alcohol solution you are working with is all that is needed.

You don’t have to get an exact ratio of alcohol to water for this concoction to work, you just have to get close enough. Landing anywhere within the 15-25% alcohol-to-water range tends to be a good rule of wrench, which is precisely why factoring-in your IPA’s alcohol strength is so paramount for producing a potent, yet completely paint-safe concoction.

This is where people tend to get befuddled, as visions of percentages, numbers, and fractions trigger unpleasant memories of 3rd period math class. We get it. We hated math class just as much as the next guy, which is precisely why we created the following simplified formulas.

Quick Tip: While a 50%, 70%, and 91% grade rubbing alcohol will work just fine once blended into an IPA spray solution, we find that the 99% stuff tends to evaporate way too quickly. Since it won’t linger on a surface, a stronger rubbing alcohol will not deep-clean the way milder grades do, and therefore we do not recommend using the “stiff stuff” in an IPA spray.

Step #1: Buy the Right Supplies

To create an IPA prep spray that’s worth a damn, you will need the following supplies.

- (1) large plastic spray bottle

- (1) 16 oz. bottle of 50%, 70%, or 91% isopropyl alcohol

- (1) 1 gallon jug of distilled water

- (5) ultra-plush microfiber towels

Quick Nerd Note: The reason why you want to use water that has been distilled in an IPA prep spray, is because it’s as close to neutral as it gets. Devoid of minerals, impurities, and chemicals, distilled water is far less prone to leaving hard water spots when compared to other forms of H2O.

Step #2: Balance Your Blend Around the Strength of the IPA

Supplies obtained, you’ll need to formulate your alcohol-to-water ratio. Since there are several strengths of IPA on the market, we’ll start off with the 91% blend, and work our way down from there, ignoring the 99% stuff for the previously stated reasons.

91% IPA

If you are mixing-up a 32-ounce bottle of IPA spray, you’ll need 6-ounces of 91% IPA, before topping-off the rest of the bottle with distilled water. This will allow you to achieve a total IPA ratio of around 17%, with 7-8 ounces of IPA being on the heavier handed end of the spectrum.

70% IPA

For a 70% IPA solution, start with 8-ounces of alcohol, filling the rest of the spray bottle with distilled water. This will give you a 17.5% IPA spray solution ratio, whereas a 9-ounce formula would put you just a fuzz below that 25% threshold.

50% IPA

If you are in search of a milder mixture, try blending 8-ounces of 50% strength IPA with 24-ounces of distilled water. This will create a 12.5% IPA spray that can be bumped-up a notch by adding a dash more of alcohol to the mix. Just be mindful that exceeding more than 14-ounces of 50% IPA in a 32-ounce batch will result in a solution that is entirely too strong for most ceramic coating surface prep situations.

Quick Nerd Note: Unless you are stripping away wax or removing massive globs of tree sap from your vehicle, the use of a 50/50 IPA blend is completely overkill, and can cause streaking. High concentrations of isopropyl alcohol can also damage clear coats and softer plastics like headlight covers if allowed to soak-in for too long. So skip the 50/50 blend and stick with the formulas listed above for safe and effective results.

How to Apply IPA Spray

The key to using IPA spray as a surface cleaner ahead of a nano ceramic coating install, is to follow the “spray and wipe away” technique. You don’t want to leave the solution sitting on a surface for too long, so spritz with the bottle set to the finest “mist” setting, and work quickly.

Hitting one panel at a time is always a good rule of wrench to follow too. Not only will this prevent the IPA spray solution from damaging surface materials, but it will also help eliminate any oversights on your end.

As you go, be sure to always wipe the sprayed area with a clean microfiber towel that is dry to the touch. When the towel gets too moist, set it aside, and swap-in a fresh one to prevent excessive surface IPA spray build-up and streaking.

Quick Tip: Save the wintergreen for your favorite chewing gum, and always opt for aroma-free rubbing alcohol. There’s a huge difference between having a car that looks “minty fresh,” and owning one that smells like a big-ass tin of Altoids.

Parting Shots

When using an IPA spray as the final prep step ahead of a DIY ceramic coating application, you must remember that this is your last shot at removing debris from your vehicle. Anything that is missed during this crucial last sweep will be encapsulated within the ceramic coating, and thus, become a semi-permanent part of the car’s exterior.

So blend properly, work methodically, move quickly, always keep a fresh stack of microfiber cloths on hand, and when in doubt, don’t hesitate to reach out. The AvalonKing team is always happy to help, because your success is our passion, even when it is something small, like blending your own IPA spray.

26 comments

Dale Pearl

The dilution is going be ratio-based. At approx. 90% IPA 4 parts distilled water to 1 part IPA. 8 ounces of water 2 ounces of IPA.

The dilution is going be ratio-based. At approx. 90% IPA 4 parts distilled water to 1 part IPA. 8 ounces of water 2 ounces of IPA.

Will

How much dilution for a 12oz bottle?

How much dilution for a 12oz bottle?

Dale Pearl

Hi there! Ideally, you dilute the IPA down to between 15 and 25%. so 1/4 strength of 75% IPA would be 19% IPA so that should be fine. 1 portion IPA and 3 portions water if my math serves me.

Hi there! Ideally, you dilute the IPA down to between 15 and 25%. so 1/4 strength of 75% IPA would be 19% IPA so that should be fine. 1 portion IPA and 3 portions water if my math serves me.

AA

Hi Im in Asia where the IPA is 75% not 70%, so what is ratio for dilution.

Excited to use the product.

Thanks in advance!

Hi Im in Asia where the IPA is 75% not 70%, so what is ratio for dilution.

Excited to use the product.

Thanks in advance!

Kevin

If we follow the science guidelines we all learn at school, it is always chemicals to water. I believe this is to avoid an instant reaction with a chemical (like acid) to a small amount of water and avoid spitting or boiling, which may spray you. IPA is probably safe, however may as well keep good practices going when mixing chemicals to water.

If we follow the science guidelines we all learn at school, it is always chemicals to water. I believe this is to avoid an instant reaction with a chemical (like acid) to a small amount of water and avoid spitting or boiling, which may spray you. IPA is probably safe, however may as well keep good practices going when mixing chemicals to water.

Tim Charlet

Hi there:

1) IPA won’t remove 2 layers of 9H ceramic coating. This requires a specialized chemical solution or polishing the coating off. 2) If you’ve polished the vehicle – 40/60 dilution IPA to Distilled water works well.

Hi there:

1) IPA won’t remove 2 layers of 9H ceramic coating. This requires a specialized chemical solution or polishing the coating off. 2) If you’ve polished the vehicle – 40/60 dilution IPA to Distilled water works well.

Indrockz

2 Questions:

1. What should be the dilution % of IPA for removing 2 layers of 9H ceramic coating ? Plz let me know the steps for the same..

2. What should be the dilution % of IPA in order to remove excess silicon oils post polishing prior Waxing/Sealant prep ?

Thanks you!!

2 Questions:

1. What should be the dilution % of IPA for removing 2 layers of 9H ceramic coating ? Plz let me know the steps for the same..

2. What should be the dilution % of IPA in order to remove excess silicon oils post polishing prior Waxing/Sealant prep ?

Thanks you!!

Ara Gureghian

ALL YOUR VIDEOS are fantastic! You have left me with no questions to ask!!! Watch all the Videos and especially read the comments, all the answers are here… Just wanted to Thank You for your diligence.

ALL YOUR VIDEOS are fantastic! You have left me with no questions to ask!!! Watch all the Videos and especially read the comments, all the answers are here… Just wanted to Thank You for your diligence.

Dale Pearl

Great question Randy!

The standard procedure for applying multiple coats is to wait for 1 to 2 hours between coats. If performed in a short period of time no additional prep work would be required.

Great question Randy!

The standard procedure for applying multiple coats is to wait for 1 to 2 hours between coats. If performed in a short period of time no additional prep work would be required.

Randy Everett

What is the procedure for applying 2 coats of ceramic coating?

Thanks

What is the procedure for applying 2 coats of ceramic coating?

Thanks