Late night infomercials, overseas online purchases, the clearance bin down at the local dollar store… everywhere you turn, sub-par products are prepped and ready to “underperform as promised.”

It’s not like the ceramic coating game is much better. Here at AvalonKing, we cannot count the number of times we’ve been told by a potential customer that they will be going with a competitor’s product because it has been engineered to be stronger, last longer, and deflect airborne debris better than our Armor Shield IX nano ceramic coating.

Then, a month later they message us, sheepishly admitting that the “magical tincture” they spread across their vehicle had failed after just a few weeks, and that they would like to benefit from AvalonKing’s 2-year protection guarantee.

Don’t sweat it.

Sourcing straightforward information about how ceramic coating hardness levels translate to real world protection is not easy. Discussions about the importance of understanding the difference between product ingredients, curing strengths, and how ceramic coatings are tested for durability and long-term resiliency are equally difficult to source.

Today we’ll discuss what ingredients make a high-quality ceramic coating ultra-strong. We’ll also take a look at the scientific experiment that determines a cured ceramic coating’s strength and scratch resistance levels, and offer a handful of tips for getting that nano ceramic coating to last longer.

9H Hardness Levels Explained

A 9H hardness level refers to a surface coating’s ability to resist scratches that have been based upon the pencil hardness scale. You may be familiar with this scale, if you have ever gone shopping for art supplies, and realized that there are a plethora of pencil drawing options to choose from, each engineered to provide different results.

Long gone is the “lead” that was packed into the pencils of yesteryear, and in its place resides graphite, a non-toxic mineral that rules at marking surfaces, and if pushed hard enough, marring them. But how easily a graphite pencil can scratch a surface depends upon more than just the amount of force being exerted, but composition as well.

“Graphite and diamond have the same composition but completely different properties.“

--Geology.com

On one end of the spectrum sits the 9H-rated graphite pencil, which not only delivers a lighter line, but also a far stronger scratch. Whereas a lower pencil grade, with a B-rating, will be far softer, and leave markings that are considerably darker in nature.

So what does this mean for ceramic coating surface protectants, like Armor Shield IX? Essentially, a 9H-rated nano ceramic coating has the ability to resist the scratching strength of a 9H pencil, the sharpest and hardest pencil on the planet.

But outside of grabbing a bunch of art supplies and scratching the shit out of your car, how does one go about testing a ceramic coating’s hardness levels? Well allow us to elaborate…

The “Wolff-Wilborn” Pencil Hardness Scale

Contrary to the ceramic coating myths circulating on the internet, these automotive protectant products are graded on the “Wolff-Wilborn” pencil hardness scale, and NOT the Mohs scale. A topic that we will discuss in greater detail a bit later.

Grading a pencil’s hardness level revolves around applying controlled amounts of pressure to a surface with a series of pencils, starting with the mildest form of graphite, and working upward from there. A hardness level is only determined when a particular grade of pencil leaves its mark on the surface.

Quick Nerd Note: In the automotive manufacturing arena, it is not uncommon for the pencil hardness scale test to be implemented on a multitude of coated surfaces, with paint, clear coat, and undercoating durability testing being the most prominent.

While there are numerous pencil hardness testing tools on the market, all of these contraptions are engineered to complete the same task: Apply carefully calibrated amounts of pressure at precise angles and speeds in order to determine a surface’s strength.

Quick Nerd Note: If the highest possible grade on the pencil scale is 9H, how on earth are some ceramic coating manufacturer’s achieving 10H ratings for their products? They aren’t. A 10H-rated ceramic coating would essentially have the same hardness level as a diamond, which would make for one hell of an expensive bottle of ceramic coating!

What is the Mohs Hardness Scale?

Friedrich Mohs is the gentleman accredited for the invention of the hardness scale that measures which minerals or metals damage one another. The Mohs hardness scale starts with talc, the softest mineral of the lot, which comes in at a milquetoast 1 on the scale.

From there, it proceeds to cover everything from fingernails and steel nails, to drill bits, knife blades, calcite, apatite, and topaz, until it finally reaches diamond status. Just like the clearance level on your uncle’s membership card for that underground club in Amsterdam he occasionally frequents.

Based upon the image above, it appears that our friend “Captain Quartz of the Silica Kingdom of Awesomeness” comes in at a respectable 7 on the Mohs hardness scale. Anything less potent than that will more than likely fail to scratch the surface of a fully cured, 9H-rated ceramic coating.

So unless some manufacturer is crushing-up diamonds into nanoparticle powder, and then infusing it into their products, that 10H+ level of protection you see being marketed online is 100% pure-grade bullshit.

What’s Inside That Bottle of Ceramic Coating?

While we can’t speak for the other guys in the ceramic coating gladiator pit, we can tell you that Armor Shield IX is comprised of a liquid polymer that’s been infused with a collection of chemicals and natural ingredients.

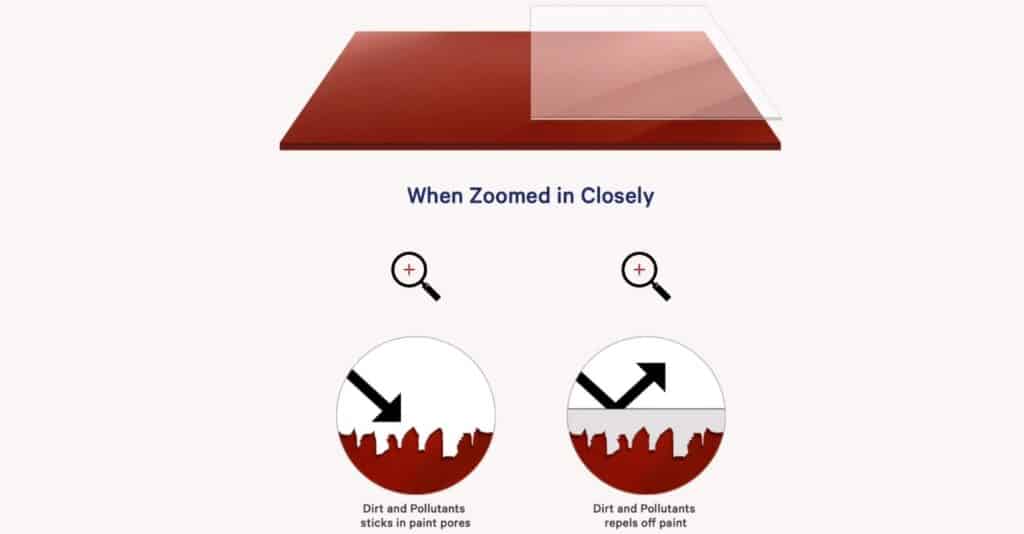

Once allowed to fully cure, the silica, or silicon dioxide (SiO2) in this concoction forms a semi-permanent layer of protection that is more akin to an invisible, ultra-hard, quartz crystal shell than a simple surface coating.

But it’s not just the SiO2 that makes a ceramic coatings harder than a sweaty Paul Hogan with a big-ass Crocodile Dundee knife in hand. There are several ingredients that help make that nanoparticle layer of Armor Shield IX protection last anywhere from 2–5 years.

Nano SiO2: If polymers are the backbone of a quality nano ceramic coating, then silica, or silicon dioxide (Si02) is the connective tissue that holds it all together. This quartz crystal derived inorganic material measures less than 100 nanometers in size, which explains the whole “nano” side of the nano ceramic coating namesake. These particles are so small, that they have been recorded at less than 1/10,000 of a millimeter under a microscope.

Nano TiO2: The often overlooked, and seriously under-appreciated cousin of SiO2 is titanium oxide (TiO2). Although this mineral is commonly found in antiseptic pharmaceuticals, when added to ceramic coatings, it boosts hydrophobic effects, and helps keep surfaces devoid of liquids and sticky contaminants.

Activation of Fluorine: Reducing corrosion and oxidation on metallic components, and making surfaces easier to clean is what makes makes fluorinated polysilazanes so spectacular.

Brightening Silicon Particles: Within each bottle of Armor Shield IX, you will find brightening silicon particles. These chemicals serve as a form of boosting the bond within the ceramic coating, thus allowing it to properly cure atop porous surfaces, all while adding additional shine.

Quick Nerd Note: The percentage of SiO2 within certain professional-grade ceramic coating products typically eclipses 95%. In contrast, most DIY nano ceramic coatings weigh-in well under 80%, with the really good stuff, like Armor Shield IX, landing just above 80%. This balance makes the product incredibly strong, all while keeping it super easy to apply.

Why Ceramic Coating Hardness Levels Matter

So when it comes to gauging nano ceramic coating strengths and longevity, how much does a hardness level matter? A metric shit-ton.

The hardness of a ceramic coating correlates to its projected longevity rating, ability to prevent scuffs and scratches, hydrophobic properties, and overall UV resistance. This make a 9H-rated nano ceramic coating the ultimate protection product for clear coatings, headlights, windshields, vinyl wrap, carbon fiber, chrome, powder coat, PPF, and even fiberglass.

Whereas car wax will last just a month or two if you are lucky, and paint sealants only repel contaminants for up to a year max, 9H-rated ceramic coatings provide protection anywhere from 2–5 years on average. And while paint protection films (PPF) have the ability to shield surfaces for even longer and resist things like rock chips, they remain extremely expensive to buy and install.

That being said, picking a ceramic coating based on its hardness levels is only one piece of the proverbial surface protection puzzle. The silica concentration within a ceramic coating protectant is what will determine if it has the ability to last longer and perform stronger than the next product on the shelf.

So keep those percentage numbers in mind when you are comparing products, because you don’t want to go too low, but you also don’t want a sticky mess on your hands because you went too high.

Quick Nerd Note: Products with extremely high SiO2 contents may be super tough, but they tend to be tough to work with due to their sticky nature. These kinds of products are typically reserved for licensed ceramic coating shops, where trained professionals with years of experience install the coating in a temperature and humidity controlled environment with the help of specialized tools.

Parting Shots

The key to formulating the perfect nano ceramic coating, is to balance a higher percentage of silica, with just the right amount of “fillers” so that it goes on smooth, while still offering unrivaled protection and shine.

Achieving a balance that hovers between strength and ease of application is but one of the many reasons why AvalonKing’s Armor Shield IX remains the highest rated 9H-certified consumer-grade nano ceramic coating on the planet.

So if you are looking for an affordable, filth resisting, water-repelling, shine-inducing DIY solution that kicks swirl marks to the curb, and lasts a really long time, give Armor Shield IX a shot. With its ultra strong composition, and 2–year satisfaction guarantee, there’s little about it to not like, especially since it only costs $69.99 a kit.

1 comment

O'Keefe's Prestige Detailing

Highly informative blog post, well done. I’m learning about ceramic coating to incorporate into my detailing business and this helped clear the air for me about ceramic coating content and the hardness scale comparison.

Highly informative blog post, well done. I’m learning about ceramic coating to incorporate into my detailing business and this helped clear the air for me about ceramic coating content and the hardness scale comparison.