May it be a discussion about ceramic coating powder coated wheels, or mulling over the mistakes people make while detailing their cars, some of the best blog topics come from our customers.

A few weeks back, one of our long-time customers posted a comment, asking whether or not Armor Shield IX could be used on plastic surfaces, specifically, after cleaning LED headlights.

The act of applying a nano ceramic coating on plastic surfaces still harbors a fair deal of confusion, especially when it comes to transparent components, like headlamps and tail lenses.

But as you shall soon see, car lights aren’t the only pieces of plastic that will benefit from a little detailing and nano ceramic coating magic. As long as it isn’t a foamy or super supple kind of plastic, chances are you can protect it with a nano ceramic coating. This includes motorcycle components, interior trim, and engine bay parts!

In the following guide, we’ll discuss the kinds of plastic surfaces that benefit the most from nano ceramic coatings, and the products you will need to complete the restoration process. We’ll also cover a few of our favorite plastic prep tricks, some choice Armor Shield IX application techniques, and a few “Quick Nerd Notes” for all you trivia buffs out there.

So enough with the introductory stuff. Let’s get that plastic looking fantastic!

Can Ceramic Coatings Be Used On All Types of Plastic?

Nano ceramic coatings coat and cure atop hard plastics the same way they do when applied to metal, carbon fiber, and glass. A high quality nano ceramic coating can be used on pretty much any plastic surface just as long as it is not prone to flexing and bending.

Although there are certain kinds of plastic that benefit more from a nano ceramic coating’s properties than others, the way in which the two man-made products interact with one another tends to be the same across the board.

Regardless as to what sort of plastic or polymer you may be coating, all of those microscopic nano particles of SiO2 (quartz) and specially engineered hardeners packed within each bottle of Armor Shield IX will penetrate any peak, valley, pocket, or pore they come across.

Once this nano technology is allowed to seep into and solidify atop a plastic surface, all of those imperfections and pockets become part of a super hard, ultra thin crystallized shell of protection.

Being that a nano ceramic coating is also completely transparent, it is 100% safe to use on headlights and taillight lenses, as well as clear coated and both painted or unpainted hard plastics.

So say goodbye to hazy yellow headlights and faded black plastic trim, because once these parts have been ceramic coated, things like UV ray damage and road pollution will no longer be of a concern.

When Should a Nano Ceramic Coating Be Used On Plastic?

One of the more common myths about nano ceramic coatings, is that they hide and repair damaged and unsightly surface blemishes. This is completely FALSE.

Despite being quite the modern luminary marvel, plastic headlights in particular are prone to absorbing all manner of airborne filth. Exposure to natural elements like pollen and tree sap, as well as all of the man-made crap that gets kicked-up along the highway results in headlamps turning from pristine pieces of plastic, into hazy eyesores.

So while a nano ceramic coating may protect whatever hard surface is beneath it, it also magnifies what it coats. So if you have hazy headlamps, don’t expect Armor Shield IX to magically transform them into crystal clear sources of illumination. It’s only going to make those nasty-looking lenses look all the more unattractive.

This is why we suggest either applying Armor Shield IX on brand-new plastic, or after it has just been restored, a topic that we will discuss in detail momentarily.

Quick Nerd Note: There are certain products that are marketed as a “plastic and rubber specific ceramic coatings.” The issue with many of these products is that their silica (SiO2) percentages tend to be a bit on the low side, which means they do not last very long and will not offer a lot of protection.

3 Reasons Why You’ll Want to Ceramic Coat Your Car’s Plastics

Those who are familiar with nano ceramic coatings typically assume that their primary occupation is protection, and for the most part, that’s completely accurate. Hydrophobic properties make things like bird crap, tree sap, road grime, and other contaminants bounce off a ceramic coated plastic, all while preventing things like UV rays from weakening its structure.

However, there are some other benefits that come with applying a coating to plastic surfaces.

Enhanced Vibrancy

A high-quality nano ceramic coating will both magnify whatever is beneath it, and add a sumptuous slathering of vibrancy to the equation. On a painted plastic surface, this results in deeper colors and a more vibrant shine, while unpainted plastics develop a darker depth that makes them appear wet, without being super shiny.

Say Goodbye to Bug Splatter

One of the biggest problems with the plastic parts on the front front-end of modern automobiles, is that bugs like to end their miserable little lives on them in dramatic kamikaze fashion.

Bug guts and the exoskeletons that surround them are a proverbial pain in the to remove ass too.

This is due in part to the fact that insects are loaded with come packed with abrasive acids, which if allowed to harden, can permanently affix themselves to paint, glass, metal, and… you guessed it, plastic.

A ceramic coated plastic front end makes bug removal a snap, with the majority of cases requiring little more than a quick spraying with a garden hose, followed by a plush microfiber towel wipe-down.

No More Fading

When it comes to blocking UV rays and the damages associated with direct sunlight, nano ceramic coatings are the alpha male in the paint protection product pack.

We won’t overload you with nerdy details, just know that a nano ceramic coating is one oxidation repelling badass, and therefore the king f fighting plastic paint fade. for more on the detrimental side of paint and plastic fade, be sure to check-out our article on clear coat surface oxidation and the damaging effects of UV radiation.

How Long Does Ceramic Coating Last On Plastic?

If properly applied and routinely maintained with a high-quality ceramic coating-friendly car shampoo, a layer of Armor Shield IX will last just as long on a plastic surface as it will on any other material.

In fact, there is zero difference in a ceramic coating’s application, aftercare, or protection levels when it has been applied to plastic surfaces. The only dissimilarity may be in how long it takes for the ceramic coating to “flash” during application, and how quickly it cures thereafter.

Quick Nerd Note: Despite being super resilient, Armor Shield IX nano ceramic coating will not provide your car’s plastics with a lifetime of protection. However, it will repel many of Mother Nature’s dirtiest and stickiest substances, as well as the man-made gunk commonly encountered on the open road for at least 2–years. AvalonKing backs every bottle of Armor Shield IX with a 2–year performance guarantee, including when its been applied to plastics.

How to Apply Ceramic Coatings to Plastic

Before you can even begin the ceramic coating install process, the plastic you plan on protecting must be thoroughly cleaned, decontaminated, and if damaged in some way, repaired.

Here are the core steps for prepping plastic for a nano ceramic coating.

Wash

The first step in any ceramic coating prep process, is to thoroughly wash the area you plan on applying the product to with the right supplies.

To complete the ultimate two-bucket DIY car wash, we suggest starting with a ceramic coating prep car shampoo, and combining it with a high-quality microfiber chenille wash mitt.

Clay Decontamination

A clay mitt or clay towel works wonders on plastic materials, and unlike a traditional clay bar, it can be washed and reused if dropped on the ground. Claying will both remove any microscopic pieces of debris that may have embedded in the plastic, and will leave behind a much smoother surface.

For more on the art of claying cars, be sure to check out our blog article on decontaminating surfaces with clay media.

Paint Correction

If the plastic you plan on ceramic coating is painted, or is protected by a clear coat, paint correction procedures may need to be implemented. The level of repair required will vary greatly depending upon the condition of the paint and/or clear coat, so don’t hesitate to hand this task off to a pro if you don’t feel confident in your DIY capabilities.

You can learn more about the art of paint correction, here, where we go in-depth into what is required to restore damaged clear coat and paint on one’s own.

IPA Spray

The final step in the plastic surface prep phase, is to wipe the entire area down with an isopropyl alcohol (IPA) solution.

This will guarantee that you do not have any lingering debris sitting on the surface during the application of Armor Shield IX.

Ceramic Coating Plastic Installation Advice

As for the process of applying Armor Shield IX to plastic materials, you’ll find it to be about as straightforward as it gets. Just follow the instructions in the box, don’t get the stuff in your eyes, and if you feel like you need a break, crack open a cold brewskie before getting back to work.

The only issue people tend to have when ceramic coating plastic surfaces, is that it can be a tad difficult to determine when the coating has “flashed.” This is particularly true hen coating matte or unpainted black trim, as the iridescent sheen is not nearly as notable from certain angles.

Temperature

50°F (10°C)

60°F (15°C)

70°–80°F (20°–25°C)

Length of Time

4–5 minutes

2–3 minutes

1 minute

If you are having difficulty determining when you ceramic coating is flashing, you an always refer to the handy “suggested drying times chart” above. Remember, Armor Shield IX works best when applied in smaller sections, and should always be buffed away with one of AvalonKing’s plush microfiber towels after a few minutes of drying time.

Parting Shots

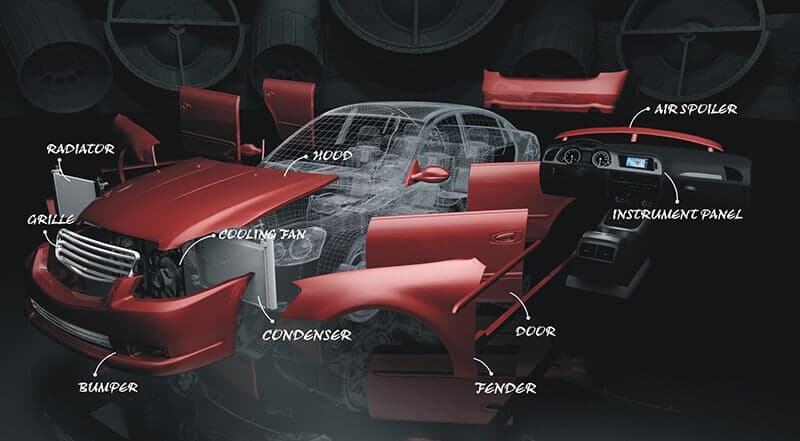

As you can imagine, everything from plastic headlights and hubcaps, to unpainted trim, bumpers, spoilers, grilles, and more can all be protected by Armor Shield IX if properly prepped and allowed time to cure.

Just remember, if the plastic bends easily, or feels rubbery to the touch, chances are it cannot be ceramic coated. These sorts of materials do best when coated with oil-rich protectants and rubber restoration products.

For everything else that’s plastic in nature, a healthy slathering of Armor Shield IX will provide the protection and shine it so desperately deserves. The open road is fraught with danger and disgusting debris, so you might as well err on the side of caution, and protect your vehicle’s plastics with the highest rated nano ceramic coating on the planet.

42 comments

Vishwanath

I have tried multiple brands plastic ceramic coating.

But after sometime the patches will start appearing on plastic surfaces. Especially on motorcycles.

Not sure what could be the issue.

It would be of great help if any solution is solution is available.

I have tried multiple brands plastic ceramic coating.

But after sometime the patches will start appearing on plastic surfaces. Especially on motorcycles.

Not sure what could be the issue.

It would be of great help if any solution is solution is available.

Maddie

My understanding of this article is yes, you can use it on your plastic as long as its not faded. However, can you use it on plastic that has just been restored with (for example) Armor All plastic restorer? If so, is there a general waiting period for how long until you can apply the ceramic coating?

My understanding of this article is yes, you can use it on your plastic as long as its not faded. However, can you use it on plastic that has just been restored with (for example) Armor All plastic restorer? If so, is there a general waiting period for how long until you can apply the ceramic coating?