Whether it’s a new professional-grade ceramic coating product, a paint protection film, or some form of synthetic wax substance, it seems that every other week a new paint protection product is coming to market.

As with any oversaturated marketspace, buyer confusion abounds in the surface protection arena, often leaving potential buyers and DIYers with more questions than answers, with one of the most common questions being: How does a ceramic coating work?

Well believe it or not, almost all ceramic coatings perform in the same fashion, and contain many of the same ingredients. That being said, there are a few scientific nuances that need to be explained if one is to fully understand how this form of paint protection works. There is also the topic of concentration levels and raw material quality which must be taken into consideration.

The info below outlines the core fundamentals behind a ceramic coating’s functional design, along with some insight into the ingredients that are commonly contained within a bottle of the stuff. You’ll also find some discussion about when a ceramic coating should or should not be used, along with some insight into what sets an authentic ceramic protection product apart from all the overhyped “snake oil” on the market.

What is a Ceramic Coating?

While ingredient percentages, content quality levels, and application instructions can all impact how a nano ceramic coating product performs, the backbone of these protectants is all the same.

Nano ceramic coatings are, in essence, a silica-infused liquid polymer solution. When allowed to cure atop a clean, hard surface, this liquid becomes super thin and flat, and in the process becomes an invisible layer of semi-permanent protection. While deflecting bullets and preventing engine fires are definitely tasks that ceramic coatings cannot complete, keeping surfaces clean and super shiny are indeed a forte.

But repelling rain and road grime, as well as scratches and airborne contaminants are but just a few of the perks this space-age stuff offers car owners. However, a follow-up question that often arises when a potential buyer eyes a bottle of Armor Shield IX is: “What makes a 9H-rated ceramic coating so much better?”

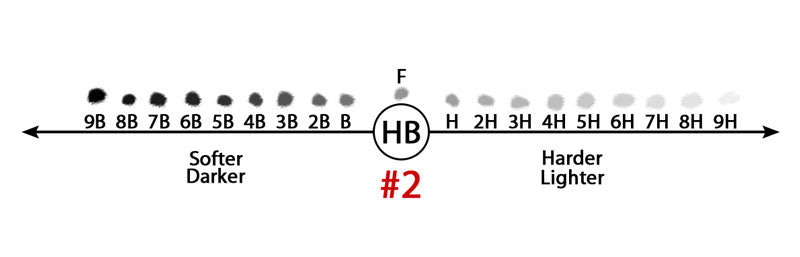

A 9H hardness rating refers to the “Wolff-Wilborn” pencil scratch resistance testing scale. As the chart above illustrates, this scale starts at 0, or HB, and goes all the way up to 9 in either direction. That being said, 9H is the hardest grade of durability within this scale, and is therefore the gold standard in ceramic coating scratch resistance testing.

So if you see a ceramic coating product that is advertised as being a certified 9H-rated scratch resistant surface protectant, the manufacturer is toting the fact that their product is the toughest on the market. Anything advertised as having a hardness level that is above 9H is complete bullshit, and should be avoided, for there is no such thing.

What is Ceramic Coating Made Out Of?

In order for a a ceramic coating to achieve a 9H hardness rating, it must be infused with the right ingredients.

While at its core resides a liquid polymer that’s comprised of millions of bonded molecules, there are some specific ingredients that must be infused into this solution in order to create a semi-permanent layer of protection possible.

Once cured, a nano ceramic coating creates a completely transparent quartz-based structure that is but the fraction of the width of a human hair. This allows the coating to repel things like UV rays and chemicals, as well as naturally occurring contaminants, like bird crap and tree sap.

While all ceramic coating manufacturers guard their recipes closely, almost all high-quality DIY ceramic coatings contain the following ingredients.

Ingredients Commonly Found in a Nano Ceramic Coating Product

Nano SiO2: This is the magic sauce that provides a ceramic coating with that super-hard, quartz-like layer of protection it requires. For those not up to date on their Chemistry 101 lessons, here’s a quick refresher on SiO2.

This chemical abbreviation represents silica, or silicon dioxide, an odorless solid that is primarily composed of silicon and oxygen atoms, which in “nano form” measures less than 100 nanometers in size. Once blended with the appropriate bonding agents and hardeners, SiO2 creates a matrix-like structure that is both extremely hard and slick.

Nano TiO2: You’ll typically find titanium oxide/titanium dioxide (O2Ti or TiO2) in pharmaceutical products, glazes, enamels, antiseptics, and even in toothpaste. In ceramic coatings, TiO2 helps improve hydrophobic water repelling capabilities, and makes for a slicker, shinier surface.

Activation of Fluorine: The dust-repelling properties of a ceramic coating is often attributed to this ingredient, as it makes it difficult for dust and debris to stick to hard surfaces. This, in turn, keeps a vehicle cleaner for longer periods of time and far easier to decontaminate.

Brightening Silicon Particles: All that shine and gloss has to come from somewhere, which is precisely what this ingredient does in a nano ceramic car coating product.

Polysilazane: The chemical and temperature tolerance levels of this chemical compound are impressive to say the least. Polysilazane is what makes a nano ceramic coating resistant to things like graffiti and certain chemicals.

3 of the Most Common Kinds of Ceramic Coating Products

Common ingredients covered, here’s a quick rundown of the three most prominent grades of ceramic coating products being offered.

Professional Grade Ceramic Coatings

Pro-grade nano ceramic coatings are precisely what they claim to be: A super high-end nano ceramic coating that is intended to be sold to, and applied by a professional detailer. These kinds of products typically contain higher SiO2 percentages, which both makes them extremely strong and longer-lasting, but also quite tricky to apply. This explains the need for them to be applied by a trained professional in a controlled environment.

Consumer-Grade Ceramic Coatings

Consumer-grade DIY ceramic coatings, are essentially the same thing as the pro-grade stuff, but with slightly lower SiO2 percentages for easier application, and a much lower ceramic coating price points. Longevity ratings typically hover in the 1–5 year range, with higher quality products boasting protection levels that sit squarely in the 9H bracket of the scratch resistance scale.

Ceramic Coating Imposters

Any DIY ceramic coating product claiming to have a “10H hardness” level, a longevity rating of more than 5–years, or is advertised as a $10 spray-on formula that can repel scud missiles is complete bullshit. Watered-down versions of the the real stuff are a dime-a-dozen, and won’t last longer than a few years, if that.

Worse yet, is the fact that many of these products require routine reapplication in order to provide a surface with “added protection.” This stuff tends to be little more than a half-step above basic car wax in the protection department, and is therefore a complete waste of time and money.

Is Ceramic Coating Permanent?

Ceramic coatings are semi-permanent, meaning that they provide a durable layer of protection that will shield a hard surface for years if routinely cleaned and maintained. While the average car wax works for around 6 weeks or so, and paint sealants last about a year, Armor Shield IX ceramic coating rocks a 2–5 year life expectancy.

When a nano ceramic coating begins to reach its maximum life expectancy, all of those water repelling hydrophobic properties will begin to fade, and that glossy shine will no longer have a rich luster. This is when a ceramic coating should be removed, at which point the vehicle will also need to be decontaminated and prepped for reapplication.

How Do You Remove Ceramic Coating?

A ceramic coating can be difficult to remove if you don’t know what you are doing. But with the right equipment, supplies, and knowledge in place, the following processes can strip any nano ceramic coating from a surface.

Chemical Removal

Despite being resistant to many kinds of chemicals, there are a few compounds out there that are like kryptonite to ceramic coatings. Most ceramic stripping products tend to sport an extremely high alkaline and/or pH content, and are therefore capable of quickly eating away nano-technology on a molecular level. However, these products also have the tendency to eat into clear coats as well, so this approach is definitely something that should be conducted with caution.

Clay Removal

If you are in the mood for a little upper body workout, then you’re going to love using a clay decontamination ceramic coating removal method. This process relies upon a clay media mitt, towel, or bar to scrape the ceramic coating from the surface. This is hands-down the safest ways to strip away a ceramic coating, as it can be used on paint, clear coat, plastic, chrome, and even glass.

Polishing Removal

Many professional detailers will use a polishing tool to remove a ceramic coating. Combined with a mid-grade cutting compound and polishing wheels in a variety of strengths, this process not only strips away the ceramic coating, but completes minor paint corrections at the same time. Just be forewarned that this method is not intended for the inexperienced, as there is plenty of room for error, with your car’s clear coat ultimately paying the price.

How Long Does it Take for a Ceramic Coating to Cure?

A high-quality DIY nano ceramic coating, like Armor Shield IX, may be super easy to apply, but it will require some time to fully cure. In Armor Shield IX’s case, AvalonKing recommends allowing the coating to cure for at least 48–hours in a dry environment before moving the vehicle outdoors.

Ceramic coating curing time also depends heavily upon the ambient air temperature, as well as things like humidity, which can slow the process to a crawl.

When Should You NOT Apply a Ceramic Coating?

A ceramic coating should not be applied to a surface that has visible damage, or is contaminated in some way. Nano ceramic coatings are designed to protect and enhance the appearance of whatever surface they cure atop, so paint scratches, swirl marks, rock chips, etching, oxidation, and other imperfections will only become all the more amplified.

As for contaminants, this kind of build-up has the ability to prevent the ceramic coating from forming a semi-permanent, matrix-like bond across a surface. This is why proper preparation is such a vital step in the ceramic coating process.

How Much Does a 9H-Rated Ceramic Coating Cost?

Most daily commuters will either plop down the dough for a professionally applied ceramic coating, or opt for a high-quality DIY product in order to save some coin. The cost difference between these two types of ceramic coatings is substantial though, which in regard to swaying purchasing decisions, oftentimes outweighs longevity and protection ratings.

For instance, a professional nano ceramic coating install can cost anywhere from $600–4,000 on average. Naturally, this depends upon the level of prep work and installation time required, as well as the going hourly rate of the installs hop itself.

In contrast, a consumer-grade DIY ceramic coating kit will run anywhere from $50–200 a pop. However, this does not include the cost of the supplies required in order to correctly prep for the application of these products. On the upside, higher-end DIY ceramic coatings typically come as a complete DIY kit, where everything having to do with applying the protectant itself is included.

Parting Shots

With so many paint protection products on the market, weeding through all of the BS in order to find an easy-to-apply ceramic coating that can keep a surface shielded and looking slick is easier said than done.

There’s a reason why Armor Shield IX continues to be heralded as the highest rated consumer-grade nano ceramic coating on the market. Not only is it a breeze to apply and super affordable, but the protection and shine it creates are as good as it gets.

But understanding how ceramic coatings work, what they are made out of, and which ones work best for you and your pocketbook is just one leg of the voyage. Hopefully the information above has provided some assistance in your journey toward a well protected and glistening automobile, and don’t hesitate to reach out for assistance, for the AvalonKing team is always eager to help.

5 comments

Tim C

Hi Karthik. I’m not quite certain what you’re requesting here. However, if you’d like to learn more about headlight restoration kits, simply Google that term, and you’ll find a lot of great articles about it. I might dive into that topic shortly on the blog, so stay tuned.

Hi Karthik. I’m not quite certain what you’re requesting here. However, if you’d like to learn more about headlight restoration kits, simply Google that term, and you’ll find a lot of great articles about it. I might dive into that topic shortly on the blog, so stay tuned.

Karthik

Head light restoration technical details please

Head light restoration technical details please

Scott Loren

I definitely learned a lot from this article. I recently bought a new car, and I asked salesperson when is a good time to put wax on it ? She mentioned ceramic coating, which I’ve never heard of. Her husband owns a repair shop, and they’re both motörhead’s. She had nothing but good things to say about ceramic coating.They send cars out to get done professionally, so she doesn’t profit from it. I do my own mechanical work on my cars, etc. I’m kicking around getting coating done professionally, or doing myself. I don’t want to screw up a brand new car, but I don’t want someone else screwing it up either.Meanwhile, new car is in my garage, and I’m driving my other car, till I figure out which way I’m going. I’m leaning towards doing it myself . Your website taught me a lot, and I’ll probably be putting order in soon. Thanks

I definitely learned a lot from this article. I recently bought a new car, and I asked salesperson when is a good time to put wax on it ? She mentioned ceramic coating, which I’ve never heard of. Her husband owns a repair shop, and they’re both motörhead’s. She had nothing but good things to say about ceramic coating.They send cars out to get done professionally, so she doesn’t profit from it. I do my own mechanical work on my cars, etc. I’m kicking around getting coating done professionally, or doing myself. I don’t want to screw up a brand new car, but I don’t want someone else screwing it up either.Meanwhile, new car is in my garage, and I’m driving my other car, till I figure out which way I’m going. I’m leaning towards doing it myself . Your website taught me a lot, and I’ll probably be putting order in soon. Thanks

Tim Charlet

Thanks, Nate – we work hard to make our articles – both informative and educational. Appreciate the kind words!

Thanks, Nate – we work hard to make our articles – both informative and educational. Appreciate the kind words!

Nate

The article was very informative and educational.

The article was very informative and educational.