Today’s automotive enthusiast wants solutions faster, cheaper, and as user-friendly as possible. We support this mindset 110% too, because here at AvalonKing, our mission is to empower people to take on the tasks that they would normally farm-out to a professional.

When it comes to exterior automotive surface protection and shine, DIY nano ceramic coating products are the ultimate evolutionary step between weak-ass car wax, and extremely strong (and expensive) paint protection film.

But what if you don’t feel comfortable with the prep or application process associated with a high-quality, 9H-rated nano ceramic coating? Do you buy a ceramic boost spray, and pray that this stand-alone protectant will provide your ride with the protection and shine that it deserves?

The difference between Wagyu beef and dried dog food boils down to ingredients and production methods, and the same can be said for DIY ceramic coatings and ceramic boost sprays.

Today, we’ll go over all of these things and more, as we investigate the facts and expose the myths surrounding ceramic boost spray products.

What is a Ceramic Boost Spray?

Before we begin, let’s make one thing abundantly clear: We are not here to bash ceramic boost spray products. In fact, AvalonKing has just recently launched its own SiO2 Boost Spray, as we know full-well how beneficial the right booster blend can be when it comes to extending the lifespan of our Armor Shield IX nano ceramic coating.

Unfortunately, when it comes to ceramic boost spray products, bullshit info abounds, with an equally sizable heap of shitty products going along with it.

In order to cut through the crap, one must first understand the difference between a concentrated, 9H-rated nano ceramic coating, and a ceramic boost spray, as the latter of these two products is merely a less concentrated version of the hardcore real deal.

Formulated around resins, ethyl alcohol, distilled water, polymers, and silica dioxide (SiO2), boost sprays rock quartz-infused content levels that range anywhere from 10–20%. Like their full-blown nano coating big brother, higher strength boost sprays typically contain greater percentages of SiO2 as well. This translates to greater longevity and hardness levels, but also a slightly more challenging application process, and the need for some serious attention to detail when it comes time for this ceramic product’s removal.

What Makes a Nano Ceramic Coating Different?

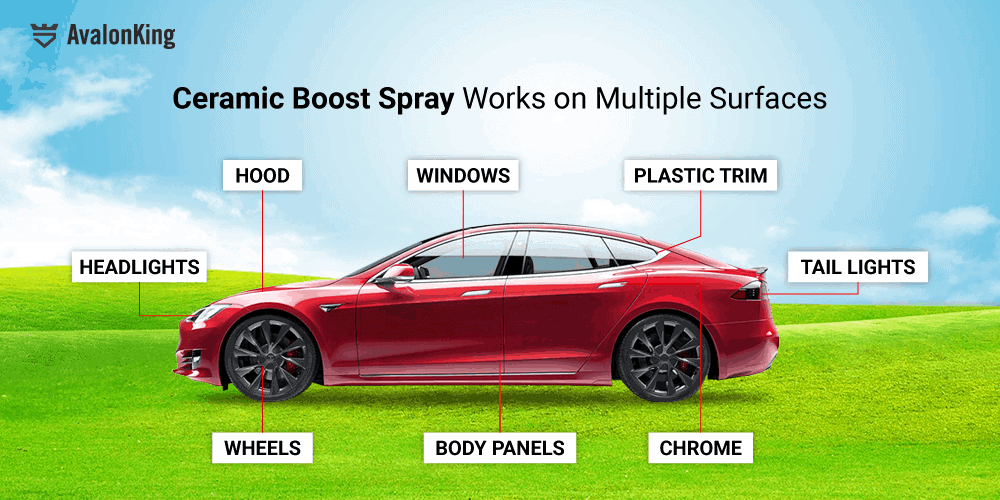

Nano ceramic coatings, like Armor Shield IX, are highly concentrated, meticulously engineered liquid products that provide semi-porous hard surfaces with a water and contaminant repelling sacrificial layer of protection. This makes them ideal for usage on automotive clear coats, glass, headlights, wheels, plastic trim, chrome, and any other external automotive component that isn’t rubbery.

But like that beef analogy from earlier, there are multiple grades of ceramic coating out there, with the most hardcore (and expensive) stuff requiring specialized tools and a professional application license.

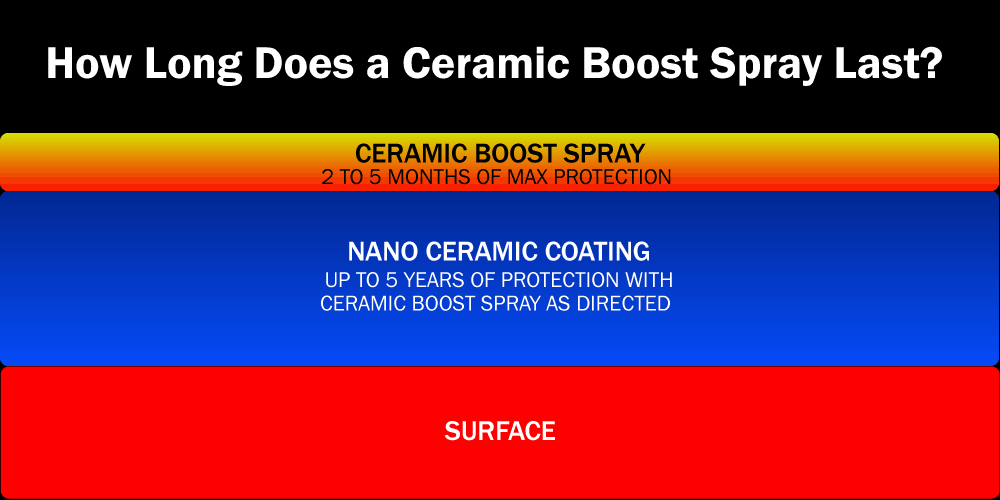

Fortunately, 9H-scratch rated products, like Armor Shield IX, can be applied in one’s garage over the course of an afternoon. Obtaining 2–5 years of protection and shine are completely achievable too, especially when the coated vehicle is routinely cleaned and rejuvenated with the appropriate products.

Do you see where we’re going with this? In theater, this is what us thespians like to refer to as: “Foreshadowing.”

How Does a Ceramic Boost Spray Work?

When applied atop a fully cured nano ceramic coating, the SiO2 within a boost spray solidifies and bonds to the coated surface, creating a glossy sacrificial layer that enhances both protection and shine. However, applying a boost spray to a non-protected surface spins a bit of a different story.

If a ceramic boost spray does not have a SiO2-infused surface to adhere to, it has no other option but to spread-out, solidify, and seep into any minor imperfections it encounters. This is why a well-engineered boost spray is such an outstanding temporary stand-alone solution, and why people looking to “fill-in the gaps” between nano coatings should consider using one.

Reasons to Use a Ceramic Boost Spray

Due to their unique formulation, ceramic boost sprays are more of an outer coating than a dedicated layer. Similar to car wax, the lower SiO2 percentage within a boost spray allow it to temporarily add protection and shine to an uncoated surface, and makes it far more affordable than full-blown nano coating products.

But unlike waxes, which do not play well with the hydrophobic repelling properties found within ceramic coatings, a boost spray can be layered atop a silica-rich nano coating product, like Armor Shield IX.

Here are a few of the more notable benefits commonly associated with ceramic boost sprays.

- Improved Shine: All of those brightening particles and glassy silica nanoparticles amplify both depth and shine, especially when layered atop an existing nano ceramic coating, like Armor Shield IX.

- Additional Elemental Protection: Despite having a much lower percentage of SiO2 than a normal nano coating, ceramic boost sprays offer outstanding resistance to things like UV rays, bird droppings, bug guts, chemicals, road salt, and more.

- Hydrophobic Properties: Unlike automotive wax, paint sealants, or hybridized blends between the two, quality ceramic boost sprays boast extremely high hydrophobic properties. This means that liquid, sticky, and dry contaminants can be easily repelled and removed.

- Multi-Faceted Badass: Ceramic boost sprays can be safely applied to everything from chrome and plastic trim, to headlights, vinyl wraps, clear coating, wheels, and even windshield glass.

What Does a Ceramic Boost Spray NOT Do?

Since a ceramic boost spray is intended to provide additional external protection to a ceramic coated or unprotected surface, it’s primary purpose in life is to serve as a “sacrificial” layer of armor.

But contrary to what those late night infomercials tell you, boost sprays aren’t an “all-in-one” magical elixir, as the following examples will surely illuminate.

- Ceramic boost sprays are NOT a waterless wash or quick detailing spray. Any product marketed as a detailing spray with SiO2 capabilities is going to have extremely low levels of silica, and therefore will not last for very long.

- Ceramic boost sprays do NOT provide scratch resistance enhancing properties, as their SiO2 percentage levels are not high enough, especially when used as a stand-alone protectant.

- Ceramic boost sprays are NOT as strong as concentrated nano ceramic coating protectants, and therefore do not last nearly as long, with 6 months being the average maximum lifespan.

- Ceramic boost sprays are NOT super-easy to remove. Sure, you can hit them with some ceramic prep shampoo and clay decontamination media to smooth them out a bit between boost spray applications, but a full-blown removal will require some polishing procedures and lots of cutting compound.

How to Apply a Ceramic Boost Spray

On the upside, when it comes to their application, ceramic boost sprays are about as entry-level as it gets. Here is a rough outline of what you need to know in order to get your spray-on.

Step #1: Make sure the surface you plan on spraying is clean, dry, cool, and free of floating debris, like dust and lint. This would be the prime time to break-out that bottle of AvalonKing IPA Spray, and decontaminate the entire exterior.

Step #2: Always utilize a shady, or covered area, when applying a ceramic spray product, and never subject it to direct sunlight or moisture until after it has fully cured.

Step #3: Apply the ceramic boost liquid evenly across one small section at a time, which typically translates to a 3 x 3 foot area.

Step #4: Use a microfiber towel or applicator pad to spread the product over the area, before allowing it to sit for the manufacturer’s recommended amount of time.

Step #5: Application downtime complete, use a separate microfiber towel or buffing cloth to remove any residue that may come to the surface, prior to moving on to the next section.

Step #6: Allow the product to cure in a protected environment, like a garage or carport shelter for at least 8–12 hours.

Quick Tip: The last step is where most people screw-up, and it isn’t entirely their fault either. Ceramic coating booster spray manufacturers are notorious for not stressing the significance of adhering to proper curing times. If a boost spray is not given ample time to cure atop a surface, longevity, appearance, and uneven coverage issues are sure to materialize.

Exposure and Aftercare

Just like any other automotive surface protectant, elemental exposure and aftercare can influence the longevity and protection levels provided by a ceramic boost spray.

While higher end SiO2 boost sprays can last up to 5–6 months before requiring reapplication, monthly “refreshes” remain the unofficial norm. This is especially true if you’re using a ceramic boost spray as a stand-alone product, as layering a fresh coat on top of an existing sublayer is the easiest way of applying fresh armor.

However, there are several elements that contribute to the accelerated breakdown of a ceramic boost spray, with the following culprits being the most commonplace.

- Water and Washing: Acid-rich rain showers, automatic car washes, not selecting the right car shampoo, overzealously using a pressure washer, and scrubbing with filthy or failing car wash mitts can all accelerate the decomposition of a ceramic boost spray.

- Windshield Wipers: Although SiO2 boost sprays can be used on windshields, wiper blades will cause the coating to wear thin in rapid fashion, so bear this in mind if you decide to spritz your vehicle’s windscreen.

- Outdoor Exposure: Despite their ability to repel UV rays, as well as both organic and man-made chemicals, ceramic boost sprays tend to degrade more rapidly when not parked indoors.

Quick Tip: Ceramic boost sprays are not intended to be applied in direct sunlight, as it causes them to streak. The same can be said if the surface is overly warm to the touch, as that too will make the spray to appear streaky, and cause it to be difficult to remove. Just like your drunk nudist uncle at the resort last summer.

Identifying Fake Ceramic Boost Sprays

The term “ceramic” is one of the most overused descriptors in the automotive detailing arena, as marketing hype and bullshit abound, even when they need not be. If a company claims that its SiO2 boost spray offers unrivaled levels of ceramic coating protection, then there had better be a shit-ton of silica, or silicon dioxide contained within each bottle.

Now, we’re not saying that everyone needs to release data highlighting the exact percentages of each ingredient found within their ceramic boost spray products. It would just be nice if companies offered some transparency in regard to what these products can and cannot do.

That being said, beware of boost sprays that are marketed as something that can be applied to a freshly washed, dripping-wet vehicle, and then simply wiped away with a clean microfiber towel post application.

Why is this an issue, you may ask? Because curing times and hydrophobic properties truly matter with this stuff.

Remember the part about how ceramic boost sprays must be allowed to cure for 8–12 hours before being exposed to water? Legit ceramic boost sprays only work when they are applied to a contaminant-free, and completely dry surface area.

So forget all of that “spray and wash” ceramic booster schlock down at the local hardware store. That stuff is only going to let you down, or worse yet, make your car look like complete crap.

Quick Nerd Note: Removing a legit ceramic boost spray can be tricky, especially when it’s been applied atop a genuine nano ceramic coating. Due to the higher silica content in premium boost sprays, all-out removal means potentially damaging the ceramic coating underneath, hence the need for the routine layering of boost sprays over the course of a nano coating’s lifespan.

Parting Shots

If you stay on top of your routine car cleaning regiment, and reapply a boost spray once a month (or after every car wash), you’ll not only extend the overall effectiveness and lifespan of the spray itself, but whatever nano ceramic coating is underneath it.

So, if you want to see your ride truly shine, while providing it with the protection it deserves, slap some Armor Shield IX ceramic coating on it, and then apply AvalonKing’s SiO2 boost spray after bath time is complete. You will be amazed by the way your vehicle’s exterior looks and performs in even the nastiest environment.

22 comments

Brandon Phanthasy

So what would we use to get everyday dust off of the car after coating it with armor shield ceramic coating?

So what would we use to get everyday dust off of the car after coating it with armor shield ceramic coating?

william johnson

Hi Dale, I did my car yesterday and it looks fantastic. I wanted to do a second coating but couldn’t get to it in that 2 hr window and now it’s too shiny, so do I let it harden, buff, wipedown and apply the second coat, also could you recommend a ceramic boost spray to use until yours is available? And again the car looks great and very easy to apply if you pay attention.

Hi Dale, I did my car yesterday and it looks fantastic. I wanted to do a second coating but couldn’t get to it in that 2 hr window and now it’s too shiny, so do I let it harden, buff, wipedown and apply the second coat, also could you recommend a ceramic boost spray to use until yours is available? And again the car looks great and very easy to apply if you pay attention.

Dale Pearl

Hi Ardianto!

I don’t recommend that. The procedure above violates the law of stacking. You always want to apply products in an order of longevity. In your example, #2 would fail prior to #3. When #2 fails so woud everything above it.

Hi Ardianto!

I don’t recommend that. The procedure above violates the law of stacking. You always want to apply products in an order of longevity. In your example, #2 would fail prior to #3. When #2 fails so woud everything above it.

Ardianto Wibowo

Wow, very great explanation. But, i still have a questions. How if we to apply the layer with these order:

1. Nano ceramic coating

2. Spray or hybrid coating with really mirror shining

3. Nano ceramic coating (again, to protect mirror shining 2nd layer to be years)

Can i do this..? Which means (3) can be bond to (2)

Wow, very great explanation. But, i still have a questions. How if we to apply the layer with these order:

1. Nano ceramic coating

2. Spray or hybrid coating with really mirror shining

3. Nano ceramic coating (again, to protect mirror shining 2nd layer to be years)

Can i do this..? Which means (3) can be bond to (2)

Dale Pearl

Hi Tobias!

Drop us an email so we can correspond directly. I have a couple of products to suggest but I’m not going to give them free advertising either.

Hi Tobias!

Drop us an email so we can correspond directly. I have a couple of products to suggest but I’m not going to give them free advertising either.

Dale Pearl

I am excited for those myself!!!

I am excited for those myself!!!

Stéphane

I wait for the shampoo and the boost spray.

I wait for the shampoo and the boost spray.

Tobias

Can you give us an idea of what Boot Spray to use in the mean time while you get yours to market?

Can you give us an idea of what Boot Spray to use in the mean time while you get yours to market?

Dale Pearl

Hi Brad!

It’s still in the works! I don’t have an ETA to give up but I hoping very soon! The Shampoos and Boost spray are in high demand and we are wanting to meet that need!

Hi Brad!

It’s still in the works! I don’t have an ETA to give up but I hoping very soon! The Shampoos and Boost spray are in high demand and we are wanting to meet that need!

brad

any updated info on the ETA of Avalonking ceramic boost spray?

any updated info on the ETA of Avalonking ceramic boost spray?